Home > Product

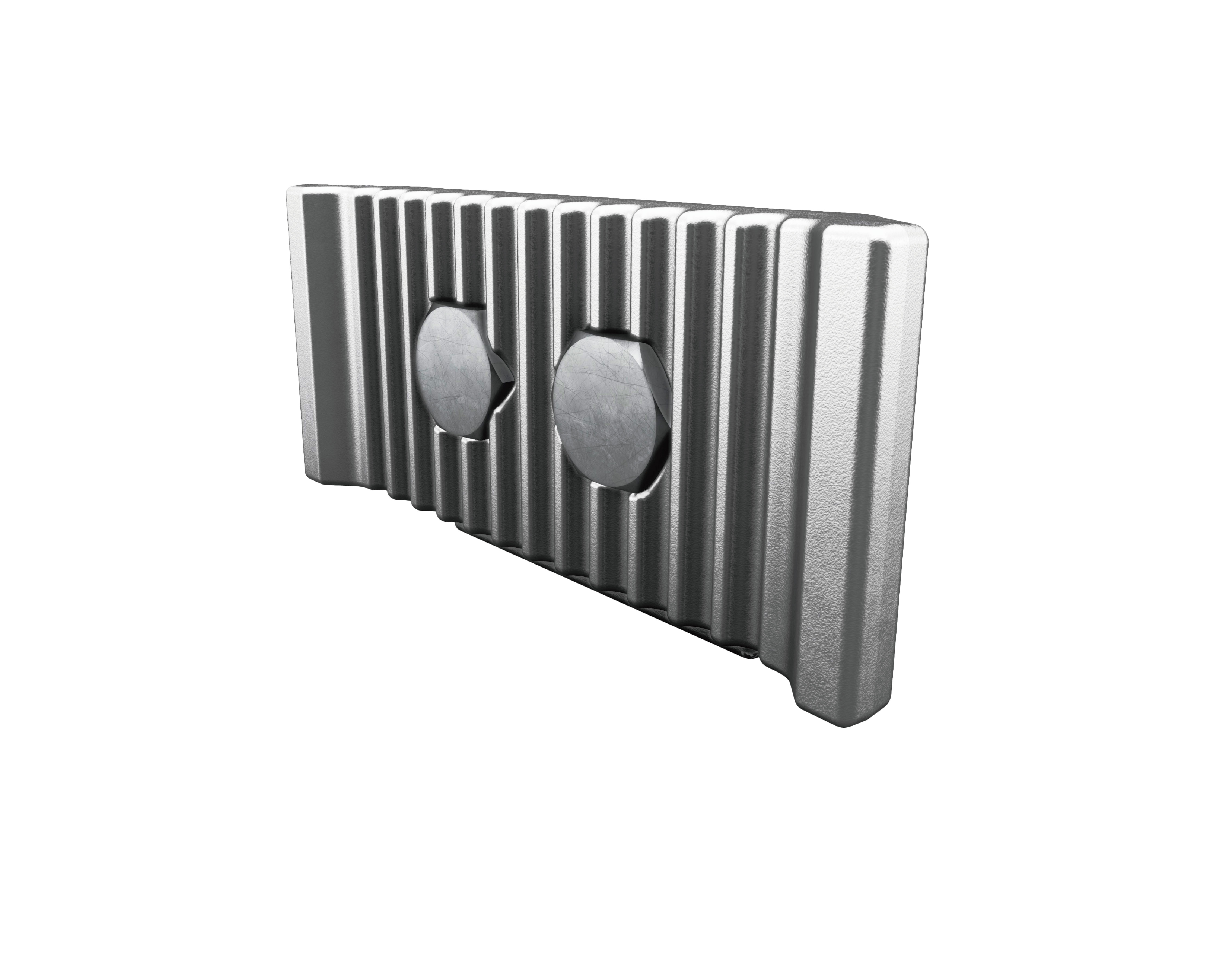

Gen-E Milling System: Transforming Asphalt Milling with Advanced Design

Discover the future of asphalt milling with Everpads' Gen-E Milling System. Our advanced suite of parts and components is purpose-built for the demands of asphalt milling machines. The Gen-E design harnesses the latest technological advancements to deliver superior performance, enhanced durability, and exceptional efficiency. Each element of the parts, from cutting tools to milling drum, is engineered with precision and attention to detail. With Everpads' Gen-E Milling System, transform your asphalt milling process into a streamlined, high-performance operation. Experience the new standard in milling with Everpads.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)