Home > Product

The Ultimate Undercarriage Parts for Heavy Construction Equipment

From our pioneering Bolt-on track pad design to our unique rubber compounds and sophisticatedly engineered crawler parts, we provide the ultimate undercarriage solutions for your heavy construction equipment. With Everpads, not only does your machine move forward, but so does your project's efficiency, durability, and success.

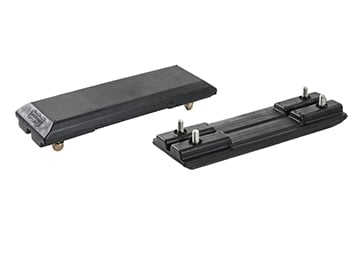

EV Pro Polyurethane Track Pads For Asphalt Milling

- Up to 1600 working hours

- Durable Pro Polyurethane Formula

- Patented Chamfer Design for Reduced Wear

EV Standard Poly Track Pads For Cold Milling Machine

- Up to 1200 working hours

- Cost-efficient Standard Polyurethane Formula

- Patented Chamfer Design for Reduced Wear

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)