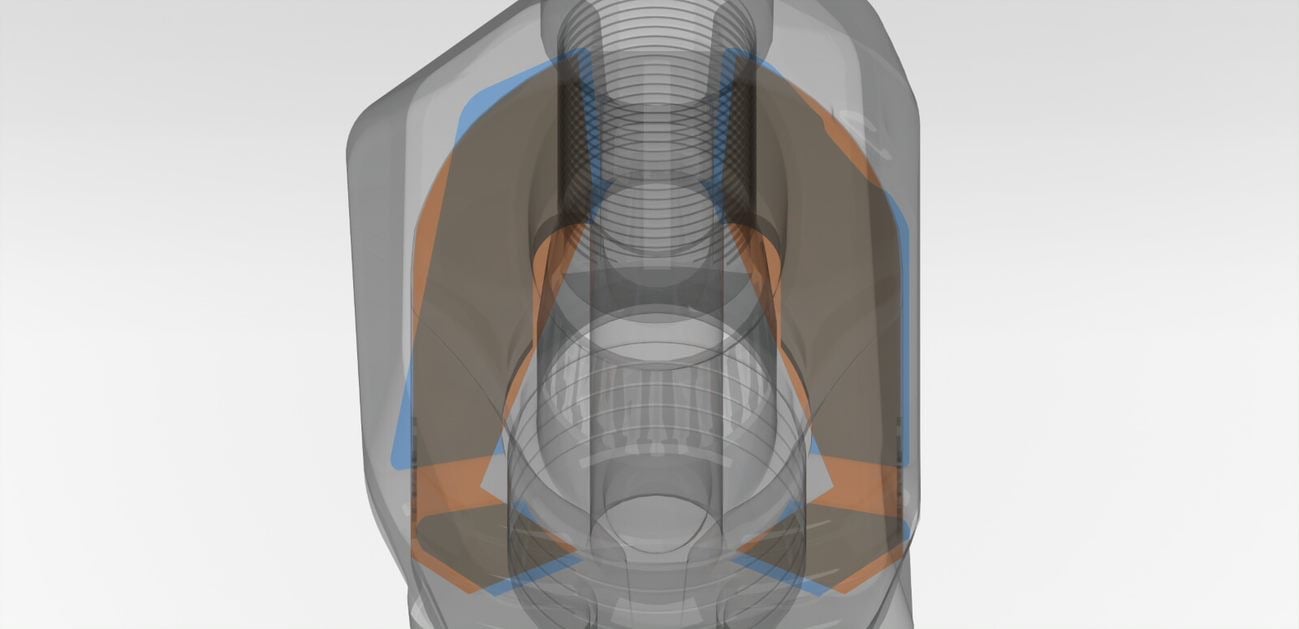

The EVERPADS quick-change toolholder system TH12 is significantly increased the wear resistance. With the perfect matching the EVERPADS tooth base, the system deliver a considerable reduction of the replacement intervals. We redesign the geometry by increasing self centering contact surfaces and optimize shank geometry between the upper and bottom part to ensure the capability of impact resistance and the service life during the heavy milling process.

Benefits of EVERPADS Road Milling Tooth Holder:

-

Reduction in maintenance requirements.

-

Significantly larger, more robust, and self-centering contact surfaces.

-

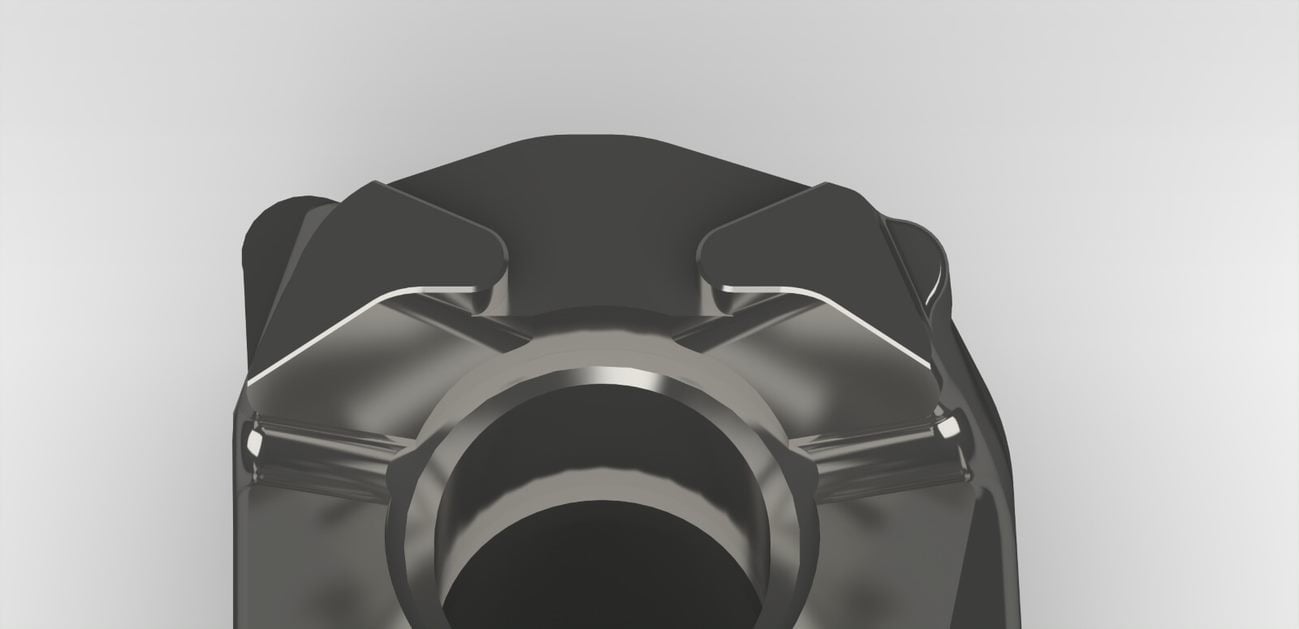

The neck of the tooth holder contact surface in combination with key technology ensures the hardness to maximize the tool holder service life.

Features of Milling Tool Base and Tool Holder Section:

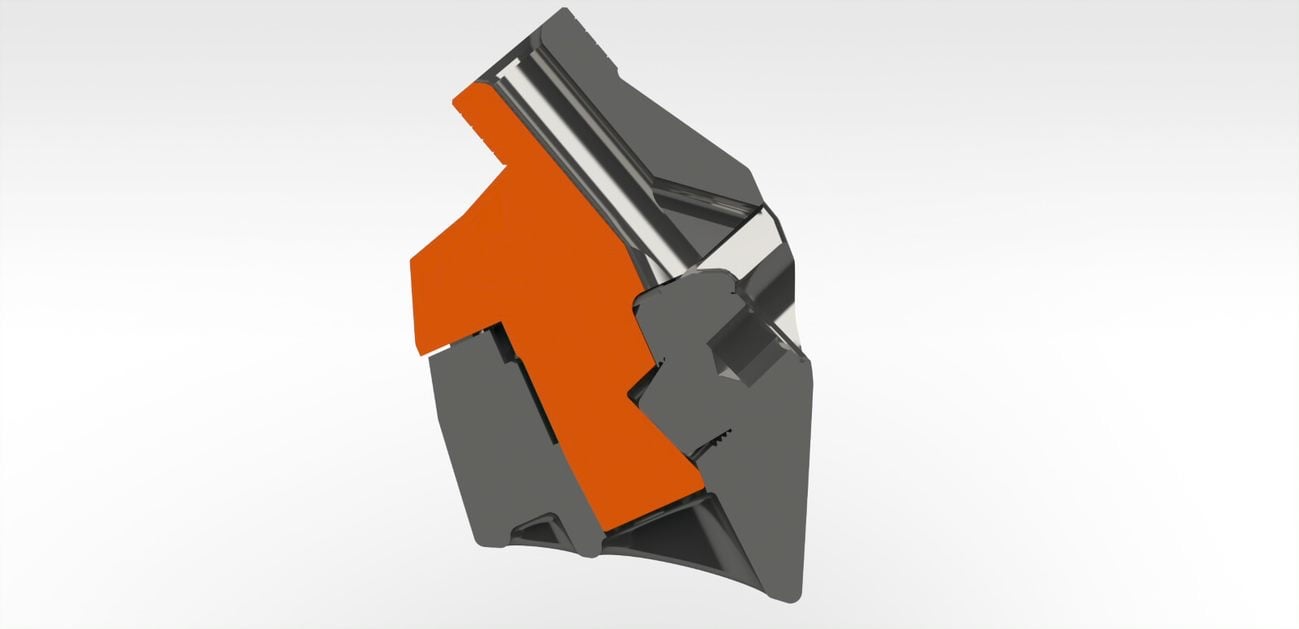

Innovate design of 7278mm2 tool base and tool holder contact surface, self-centering optimization, impact resistance, and tool holder breakage can effectively protect the tool holder

-

Highly durable with multi-process treatment on the surface increased lifespan.

-

Effortless maintenance supports easy changing of end mills.

-

Larger contact surface, higher resistance, and self-centering contact surface of tooth holder to protect and ensure the longevity of the milling drum.

- Optimized tooth holder shank patented design that increases the maximum load and anti-deformation.

EVERPADS offers a tooth holder depending on the method you want to employ to hold the end mill in place. All EVERPADS tool holders are made of high-quality materials and meet OEM standards.

Whether you perform moderate or heavy milling, the gripping force of our tool holders is customizable to meet the need of your operation.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)

_Toolholder%20General%20Feature.jpg?width=800&height=517&name=E-CommerceProduct%20Page(Sean)_Toolholder%20General%20Feature.jpg)

_Tool%20Holder%20Feature%20Card-1.jpg?width=800&height=410&name=E-CommerceProduct%20Page(Sean)_Tool%20Holder%20Feature%20Card-1.jpg)