Product Introduction

Discover the cutting-edge technology of Everpads Gen-E Milling Teeth, designed to revolutionize your road construction projects. Gen-E milling teeth feature an optimized geometry, durable carbide compounds, and high-elastic spring plates, ensuring they can withstand higher milling workloads while delivering precise, efficient cutting.

Everpads road milling teeth are provided for all ranges of cold milling machines, offering the right milling teeth for your milling operations.

With 30 years of research and innovation, our meticulous production process guarantees that each milling tooth meets the highest standards of quality and performance.

Explore the comprehensive guide to estimate milling tooth designs

Feedback from Real Road Construction Pros

Highlights

Gen-E Milling Teeth Performance:

• Achieves a 2% lower partial wear rate, addressing the most common premature issue.

Why Choose Everpads?

_Milling%20Teeth%20Feature%20Card.jpg?width=800&height=387&name=E-CommerceProduct%20Page(Sean)_Milling%20Teeth%20Feature%20Card.jpg)

Key Features and Benefits

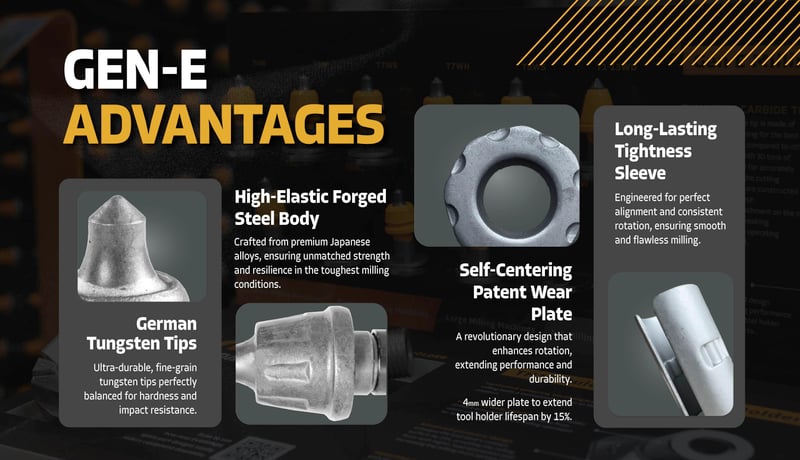

Superior Tungsten Carbide Tips

- German Material: Made from top-quality German tungsten carbide, our tips are engineered for maximum wear resistance, enabling them to cut through tough surfaces with ease.

- Optimized Design: Each carbide tip design has a different purpose, making sure that it meets your milling operations requirements.

High-Performance Steel Body

- High Wear Resistance: Our patented shape design and use of high-strength steel alloys provide unparalleled durability and protection for the tool holder.

- Enhanced Rotational Efficiency: The unique wave-shaped wear plate design ensures optimal rotation performance, reducing wear and extending the service life of your milling teeth.

Advanced Wave-Shaped Wear Plate

- Superior Hardness and Elasticity: Made from high-quality steel, our wear plates offer exceptional hardness, low wear, and excellent elasticity.

- Increased Tool Holder Protection: The 4mm thickness and 48mm diameter provide better coverage and protection, reducing friction and extending the lifespan of the tool holder.

High-Elastic Spring Plate

- Consistent Tension: Our spring plates maintain long-lasting, constant tension, ensuring that milling teeth remain securely in place while allowing smooth rotation.

- Reduced Friction and Increased Wear Resistance: Designed to prevent teeth from falling out during operation, the spring plates effectively reduce friction, enhancing wear resistance and overall performance.

Applications

- • Small Milling Machines

- • Compact Milling Machines

- • Large Milling Machines

[Optimized Your Part Selections: Choosing the Right Milling Teeth for Different Road Construction Projects]

Gen-E Milling Teeth Anatomy Blog

Customer Story

You could see they wear pretty evenly after 150 hours of working time, an average 6000 yards milled a day. You have to do the math.

EV poly pads hold up a lot longer when we twist and turn on the milling. You can see even the logo is still on it and I put in at least 600 hours on these already and their pens are holding up very well. Everpads...very good quality.

We had used other milling teeth before...and... after a probably one go around, We had to...lift up the back panel and change up the whole bunch. I mean... If we hit the manholes and water boxes, those teeth blow out, but Everpads' teeth seem to hold up pretty well. It's absolutely that they're fantastic.

"With the help of EVERPADS premium spare parts, we were able to save 40% on costs. Their milling machine parts were undervalued compared to the parts' service life, not only in price but also in performance. EVERPADS is exactly what we needed to overcome our challenges and drive our business more profitable."

Having used EVERPADS Gen-E Milling Teeth, I can confidently say that it is an excellent product for high-demanding milling task. The teeth are designed in a way that makes them resistant to wear and tear even with extended use, allowing us always to get the job done efficiently. We have definitely seen a significant improvement in our milling projects since we started using these milling teeth and I would highly recommend them to anyone looking for greater productivity without premium cost from your milling project.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)