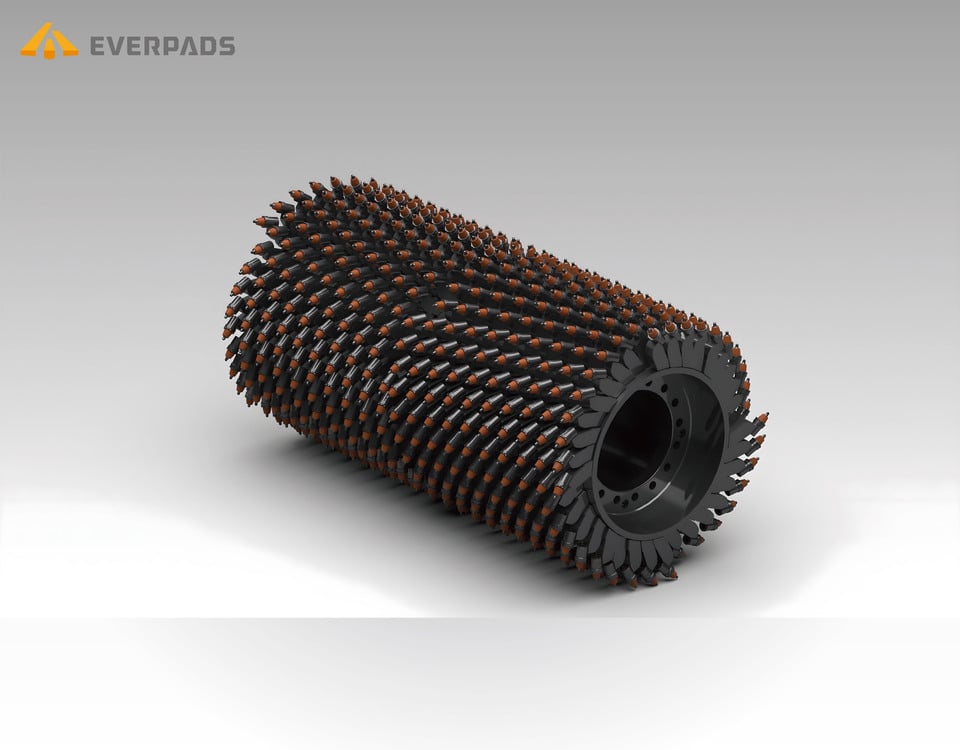

The milling drum from EVERPADS enhances the optimum use of a cold planer's potential. The intellectual manufacture technology processes can manufacture the precise and quality of milling drum's tool spacing up to 3mm. There's a variety of Milling Drum for Cold Planer in this category.

We have different ranges that depend on the tool spacing and the maximum milling depth of the machines.

Key Features and Benefits

-

It can easily cut and break out particles(materials) from the compound.

-

High welding strength and slow deformation and stress corrosion.

-

Better milling flatness with accurate angle, depth, and geometry to meet specific machine needs.

-

Easy transportation of particles to the tract of the ejector.

-

Can meet enormous demands on large volume operations.

EVERPADS have different milling drums for specific purposes, the products under this category are:

-

Standard milling drum: mostly used for removal of surface.

-

Micro-fine milling drum: For increased surface grip for large profile demands including roughening road surfaces. It is also easier for road markings removal.

-

ECO Cutter: good for concrete milling work.

-

Fine milling drum: accurate in corrective milling

The Milling Drum for Cold Planer from EVERPADS can effectively eject removed particles into the loading conveyor. No matter the thickness of the surface, it can level, smoothen it to a full-depth removal. While it easily adapts to any road conditions, its performance during operation is of a high standard.

Our milling drum features a patented tool holder, forging craft, and is properly heat-treated to meet industry standards.

Learn deep insights of Gen-E Milling Drum:

Revolutionizing Road Construction: Everpads' Gen-E Milling Drum

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)

_Milling%20Drum%20General%20Feature.jpg?width=800&height=626&name=E-CommerceProduct%20Page(Sean)_Milling%20Drum%20General%20Feature.jpg)

_Milling%20Drum%20Feature%20Card-1.jpg?width=800&height=526&name=E-CommerceProduct%20Page(Sean)_Milling%20Drum%20Feature%20Card-1.jpg)

.jpg?width=800&height=803&name=E-CommerceProduct%20Page(Sean).jpg)