After more than 20 years of experience in the road construction industry, we have seen lots of customers spend unneeded time and money on replacing milling machine parts. This is often due to using low-quality parts and/or failing to perform routine maintenance on milling machines. Fortunately, both users and manufacturers of asphalt milling machines can take proactive steps to improve machine efficiency, performance, and service life.

In this article, we delve into the common reasons asphalt milling machines underperform or fail. We'll also explore some of the consequences of using inferior replacement parts and the benefits of investing in high-quality components.

Table of Contents:

1. Understanding Component Function in Cold Milling Machine

2. Common Reasons Asphalt Milling Machines Underperform or Fail

3. Milling Machine Replacement Parts ROI

4. Milling Machine Maintenance Tips

5. Important Factors to Consider When Choosing Replacement Parts

6. Ready to Maximize the Efficiency of Your Asphalt Milling Machines?

Understanding Component Function in Cold Milling Machine

Milling Drum

Also known as the cutter drum, is a cylindrical component that holds a variety of cutting tools. The drum rotates bringing the cutting tools into contact with the ground and removing material in a controlled precise manner.

Inferior drum quality can cause materials to get stuck in the milling chamber and then damage the whole drum reducing its lifespan. It also results in uneven milling surfaces and frequent project delays.

Tool Base

The tool base supports the workpiece during operation and is normally welded on a drum, and also has the same lifespan. The tool base can be adjusted vertically, horizontally, and angularly, allowing precise workpiece positioning applications.

Inferior base quality can cause internal partial wear at the connecting area with the holder, requiring that the whale drum be replaced. Moreover, the tool base will be unable to centralize the position of the tool holder which reduces its lifespan and teeth performance.

Tool Holder

Installed on the tool base and can easily be changed if worn. Holders secure the cutting tools onto the drum. It ensures the tools are firmly in place and properly aligned, preventing vibrations or deflections during the milling process, and resulting in accurate and consistent cuts.

Inferior quality can make it difficult to centralize teeth, which reduces teeth rotation efficiency and lifespan. They can also fall off from the base, causing the base to become worn and requiring the replacement of the whale drum.

Milling Teeth

Teeth are the small cutting tools attached to the drum. They engage with the workpiece, making rapid cuts to shape and remove material effectively. The choice of teeth type, width, and material depends on the specific machining requirements.

Inferior teeth quality can result in low cutting efficiency because the design does not match the surface needs. Partial wear can occur due to low self-rotation efficiency which reduces the lifespan of the teeth. In addition, the inferior raw material and shape process consequent its short mature lifespan.

Common Reasons Asphalt Milling Machines Underperform or Fail

The successful completion of an asphalt job requires adhering to a strict project schedule. Routine equipment maintenance processes are often put on the back burner in favor of more urgent job-based tasks. Moreover, when maintenance is required, organizations often seek to save money by installing inferior replacement parts. Yet these decisions typically have the opposite effect - costly equipment breakdowns, unplanned machine downtime, and reduced productivity and milling quality.

Failing to Perform Routine Maintenance

Failing to perform routine maintenance on asphalt milling machines can lead to unplanned downtime and can negatively impact the asphalt milling process.When critical components break or malfunction, the machine becomes inoperable, leading to unplanned downtime.

A lack of maintenance can cause gradual degradation of machine performance. For example, worn cutting teeth or a misaligned cutting drum may result in inefficient milling, requiring more passes over the road surface to achieve the desired depth or finish. Reduced efficiency not only extends the time required to complete a job but also increases fuel consumption and overall operating costs.

In addition, neglecting maintenance can compromise the safety of the machine and its operators. Malfunctioning safety features, such as emergency stop mechanisms, backup alarms, or operator controls, can lead to safety hazards that necessitate immediate machine shutdown until issues are resolved.

Inferior Replacement Parts

While the temptation to opt for lower-cost, inferior replacement parts may seem appealing from a budget standpoint, it often proves to be a costly mistake in the long run. First, machines operate under harsh conditions and are subject to dust, debris, and continued wear and tear while on the job site. Inferior replacement parts are made from substandard materials that lack the durability to withstand these conditions. As a result, parts wear out quickly leading to frequent equipment breakdowns and premature replacement.

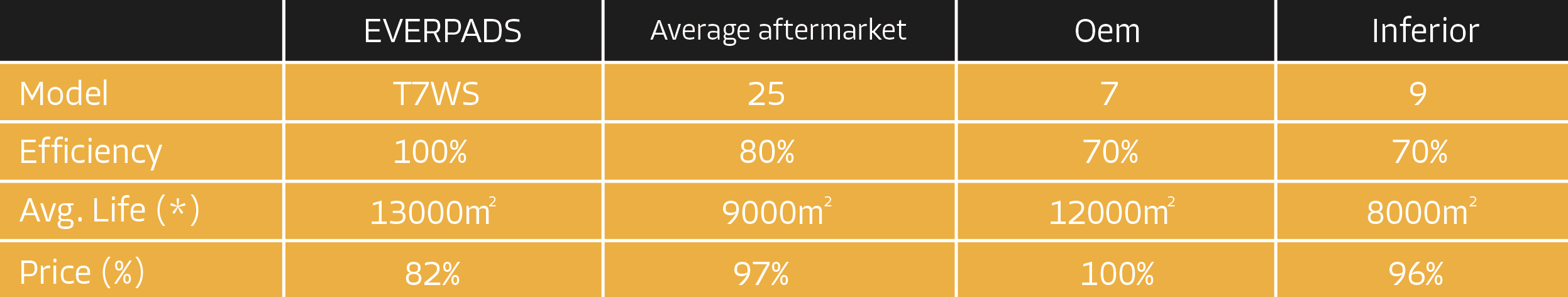

High-quality replacement parts are engineered to meet strict performance standards, ensuring optimal milling machine functionality. Inferior parts often lack the precision and quality control necessary for efficient performance. This can result in reduced milling efficiency, uneven surface finishes, and the need for multiple passes to achieve the desired results. For example, the average cold milling machine teeth need to be replaced every 24 working hours (7000-9000 square meters). But higher quality teeth such as EVERPADS road milling teeth for a cold milling machine last 25% longer (30 hours).

Subpar replacement parts that are not suitable may also ㄑcompromise the safety of both the machine operator and those working in proximity to the milling machine. And while lower-quality replacement parts may appear cost-effective initially, they often result in hidden expenses. These can include the costs for new parts, repairs, additional labor, and project delays. In contrast, investing in premium, genuine replacement parts may have a higher upfront cost but offer long-term cost savings through enhanced productivity and reduced maintenance expenses.

Milling Machine Replacement Parts ROI

Let’s consider an example that demonstrates the potential cost savings of opting for higher-quality asphalt milling machine replacement parts.

Suppose that you operate a W210 asphalt milling machine under challenging conditions, dealing with mid-hard AC pavement at a milling depth of 10cm. Your machine is equipped with 176 cutting teeth and the average replacement interval for each tooth is 24 working hours.

The cost of replacing the teeth, excluding installation, amounts to $792.

Cost Breakdown for Teeth Replacement

Let's start with the replacement of cutting teeth, a critical component of the milling machine:

In your current setup, with an average replacement interval of 24 working hours, you are spending $792 for each tooth replacement.

Assuming your machine works 1200 hours per year, you would require approximately 50 replacements annually, costing you a significant $39,600.

High-Quality Replacement Parts

Now, let's consider the potential cost savings if you were to switch to Everpads' high-quality cold milling machine teeth:

Everpads' teeth have an extended average replacement interval of 30 working hours. This means you would need fewer replacements over the course of a year – approximately 40.

At the same cost of $792 per replacement, your annual expenditure on teeth replacement would be reduced to $31,680 – an annual savings of $7,920.

Expanding Cost Savings

The cost savings don't stop there. Consider the tool holder and milling drum/tool base replacement intervals. Tool holder replacement is necessary every 1,500 working hours and costs $2,640 per replacement.

Milling drum and tool base replacement occurs every 3,000 working hours, with an expense of $50,000 per replacement.

Everpads' tool holders have an extended average replacement interval of 1,900 working hours, and their milling drum/tool base lasts an average of 3,600 working hours. With these longer lifespans, you'll reduce the frequency of replacements and save significantly.

Milling Machine Maintenance Tips

In addition to using high-quality replacement parts, it is essential to implement a proactive maintenance program for asphalt milling machines. Regular inspections, preventive maintenance tasks, component replacements, and adherence to manufacturer recommendations can significantly reduce the risk of unplanned breakdowns, extend machine lifespan, and ensure the efficient operation of asphalt milling equipment. Developing and practicing good maintenance habits can also help to extend the lifespan of the milling machine. Here are several tips and best practices for maintaining your milling drum:

-

Maintain Tools and Tool Holders. Ensure that tools and tool holders are kept in optimal condition. Regularly check the tools for signs of wear and replace them as needed.

-

Tighten Tool Holders. After the first 50 hours of use of your milling machine, tighten all tool holders to a torque of 500 Nm. Each tightening must be done using a torque wrench and the use of additional force bars is prohibited.

-

Tap all tool holders with a copper hammer every 50 working hours to check for any signs of loosening. If the tool holder exceeds its load capacity, it may loosen unexpectedly but not detach. Failure to check in a timely manner may lead to secondary damage to the machine and damage to its base.

-

Every 500 hours of milling machine use, make sure to forcibly tighten all tool holders to the manufacturer-specified torque.

-

If you detect any abnormal noise, promptly investigate the cause to avoid unnecessary losses and potential safety issues.

-

If you find that any tightening is not secure, it is important to disassemble and clean the internal mud and sand, and then reinstall.

-

After assembling the tool holder, tap it with a 1kg copper hammer to confirm that it is securely fastened.

Important Factors to Consider When Choosing Replacement Parts

When selecting the appropriate replacement parts for your asphalt milling machine, it is important to consider several factors.

Milling Teeth

First, consider the teeth, which are fundamental to the milling process. Pay attention to their rotation rate, as it directly impacts their wear and tear over time. Additionally, assess the rigidity of carbides in the teeth, as it influences their sustained cutting strength and force, ensuring efficient milling operations. Moreover, evaluate the protection designs for the holder, as they contribute to extending the lifespan of this valuable component.

Tool Holder

Moving on to tool holders, their centralization capability should not be overlooked, as it plays a significant role in addressing partial wear concerns. Furthermore, assessing the protection designs for the base of tool holders is critical since it directly impacts the durability and longevity of these critical components.

Milling Drum

Finally, when considering the milling drum and tool base, the consistency and precision of the angle welding of the tool base come into play. This aspect significantly influences the quality of the milled surface. Additionally, evaluate the alignment row of the tool base since it can prevent materials from becoming lodged in the milling chamber, minimizing disruptions and enhancing efficiency. Lastly, look for designs that help protect the holder and teeth, ultimately extending the lifespan of this component.

Ready to Maximize the Efficiency of Your Asphalt Milling Machines?

Asphalt milling machines are the backbone of road construction, and their efficiency and longevity are paramount. Neglecting routine maintenance and opting for inferior replacement parts can lead to costly breakdowns, project delays, and hidden expenses. In contrast, prioritizing maintenance and investing in high-quality replacement parts ensures smooth operations, cost savings, and project success.

EVERPADS offers a large selection of high-quality replacement parts and components for asphalt milling machines, supporting a broad range of applications. Countless manufacturers and users around the world are already experiencing the benefits of EVERPADS products. Some of the top benefits include:

- Reducing your replacement parts expense by 20% to 30%.

- Increasing machine productivity by 25% to 30%.

- Reducing unexpected and costly machine shutdowns.

- Improved milling quality.

Please contact a member of our dedicated team to learn more about our industry-leading products. Or, please visit our blog or read our whitepapers to learn more about choosing replacement parts and for tips to increase maintenance and job efficiency.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)