Are you looking for the best rubber buffer vibratory hammer (Vibro hammer)? With maximum frequency, maximum extraction, and driving force depending on the machine, you need to make sure you’re choosing the right rubber buffer that has a long service life and will keep up with your Vibro hammer.

Vibratory hammer

There are four key things to look for when picking the best rubber buffer for your vibratory hammer:

1. Rubber: The primary purpose of the rubber buffer is to protect your vibratory hammer from being damaged by the high driving force and vibrating frequency. Rubber has great damping ability, but two factors will affect the rubber’s material property. Two primary standards of the rubber:

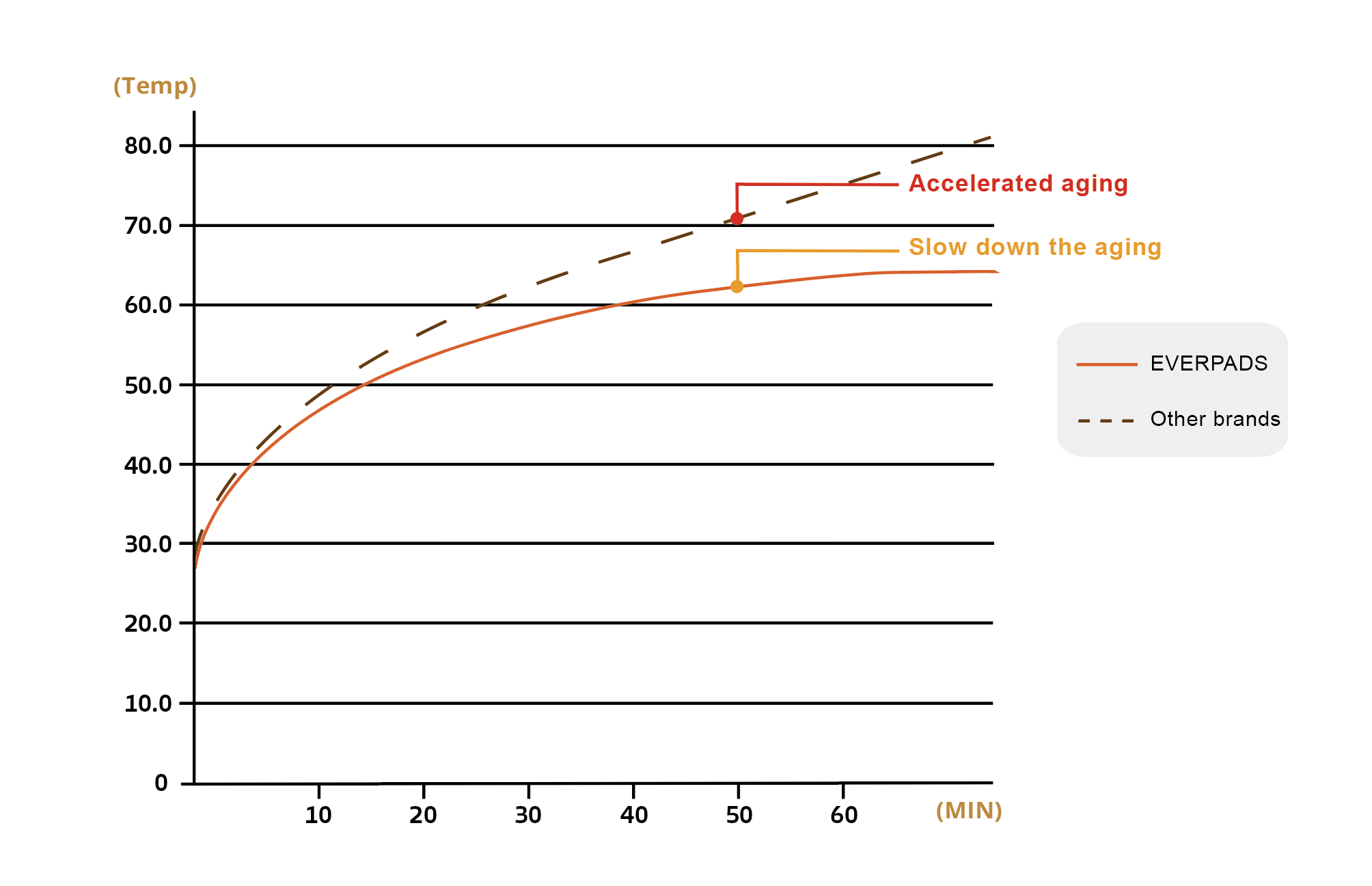

Vibration frequency: When the vibratory hammer is operating in the high constant frequency, the temperature of the rubber will start heating up. Keep in mind, when rubber is under a high temperature for a long period of time, it will cause the rubber to start aging and affect the (fatigue) life of the natural rubber. It usually becomes hardened and loses its damping capability (Choi et al., 2005). This will cause rubber buffers to start to flake off. Your vibratory hammer will need to be replaced frequently for the rubber buffer to continue with the construction.

Inferior rubber buffer: start hardening / flake off and losing Rubber buffer tears and aging damping capability

1. Driving/Pulling force: The primary work of vibratory hammers is to drive and extracting piles. Most of the projects required a heavy-duty and a full planned schedule. Other factors may reduce the rubber service life, such as engine over temperature. Excellent rubber maximizes the limit to maintain the performance of the hammer. We have seen many cases when the rubber buffers are easily deformed within three to six months, causing the rubber buffer to fracture. Bear in mind it is hard to determine whether the rubber is of good quality from appearance. You need to choose the manufacturer who can provide the pulling test for the rubber buffer.

Inferior rubber buffer easily deformed, causing the fracture

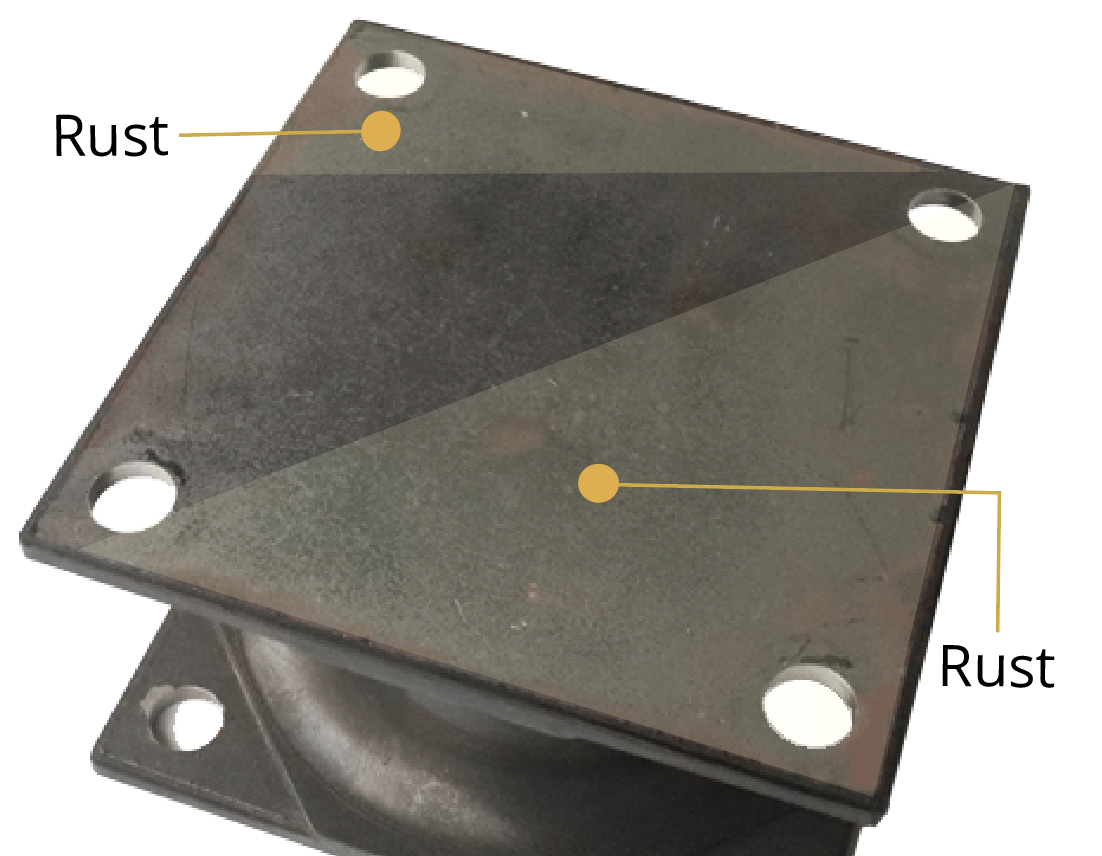

2. Steel Plate: A steel plate is the only touch point attached to your vibratory hammer that requires the strengths to prevent pulling apart from a vibro hammer or rubber. You have to choose steel plates made of high-quality material with heating, electroplating, and an anti-corrosion treatment to get the job done , no metter the severity of the work environment.

Steel plate without anti-corrosion treatment causing corrosion

Key Technology: Why EVERPADS is competent to fulfill your needs?

With over 25 years of experience and development, EVERPADS understands every critical element of the Rubber Buffer. We help our clients accomplish every project from light to heavy-duty.

- Rubber:The key technology solution(Formula E) of EVERPADS’s rubber controls the rubber temperature at 68 ℃/154.4 ℉ (see the material properties test). The Formula E effectively slows down the rubber from aging and losing property capability, increasing three times more service life than other brands.

Our clients don’t worry about shortening service life when a high vibrating frequency or workload is required.

EVERPADS rubber buffer sheer test

EVERPADS rubber buffer sheer test

EVERPADS rubber buffer sheer test

EVERPADS rubber buffer sheer test

-

Steel plate: The rubber buffer's steel plate is the only contact point with your machine. Steel plates must be capable in every server environment. EVERPADS’ rubber buffer steel plates have had the heating, electroplating, and anti-corrosion treatments necessary to handle every severe construction environment. For example, a bridge construction and marine station.

-

Mounting hole: Using reinforced steel material, the mounting hole is hard to deform or break.

-

Adhesive: After strong sandblasting and three adhesive treatments, the steel plates are guaranteed not to peel off the rubber.

-

Customize: If there is a specific case, we probably don’t carry the rubber buffer to fit your machine. Don’t worry thiugh. Just fill out the dimension in the spec form, and we will reach out to you soon.

-

OEM Solution: EVERPADS can customize the rubber buffer to meet your vibratory hammer needs (sheer force), maximize your vibratory hammer efficiency!