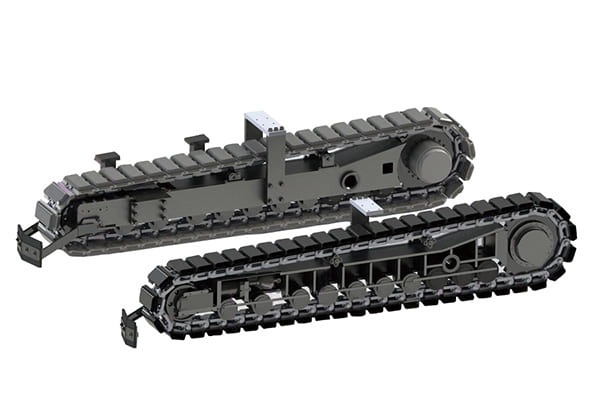

Undercarriage System with Rubber Track Pads

What are rubber track pads?

The primary purpose of track pads is to protect the road surface during the construction project. We also write an article about choosing poly or rubber track pads. The unique point of the rubber pad provides a better shock absorption capability and better traction for your heavy equipment. As said, better shock absorption performance that is bringing better stabalbility and protection for your heavy equipment. If your machine requires a higher level of traction and stability while advancing, a rubber track pad can be your best choice.

What Are the Critical Factors for Rubber Track Pads:

Life Span

Physical Property:

Rubber: Aging (fatigue) speed is the major component of rubber pad's life span, and heat causing the rubber to start aging and losing its properties capabilities. Mostly rubber pads carry heavyweight equipment, causing pressure, generating heat to the rubber pad, and affecting the service life. Typically, when replacing your rubber pads, you will see the cracks, hardening, and losing damping capabilities. These are the symptoms caused by rubber aging. So, good rubber pads require the capability to slow down the aging speed that provides longer service life.

Inferior Rubber Property (flaked)

Shock Absorption:

One of the main points of choosing rubber pads for your undercarriage system is the excellent shock absorption capability. Two factors make great shock absorption capability, the rubber's:

-

Repulsion power

-

Supporting force

Design:

Heavy machines work in different surface conditions. Rubber pads are the critical point to support machine mobilities. The great design of the rubber pad can have more excellent advancing agility performance and minimize extra wear and tear by bad design of rubber pad.

Why EVERPADS Is the Best Rubber Pads for You?

So why should you choose EVERPADS for your rubber track pads? EVERPADS is devoted to developing multiple patent designs which really solve client's problems. Our rubber pad can bring the best result for your construction machine.

Key Technology

Rubber

EVERPADS applies one of the core technologies, Formula E, to our rubber track pads that slow down the rubber's aging ( fatigue) speed, controlling the temperature at 63 ℃ or 145.4 ℉, resulting in longer service life and remaining excellent properties capabilities during the on heavy-duty construction project.The special compound of rubber that produces excellent absorption capabilities of the rubber that protects your undercarriage system and enhances the operator's experience.

Chamfer edge patent design

This patented design effectively optimizes the advancing quality and steering agility. Creating the space between the edges and pads avoids unnecessary wear and tear.

Built-in plate patent design

The next reason you should choose EVERPADS is our built-in plate patent design that provides the greater colloid stability of rubber pad that prevents disinformation while advancing under the heavy equipment.

Bolt-on design

Rubber track pad provides a more straightforward installation and cost efficiency solution.

Responsibilities

Every rubber pad has been through quality and properties inspection. Fit perfectly with your existing grouser. EVERPADS had been in partnership with most of the existing brands. Application for cold milling machine, excavator, paver.

The Technology of EVERPADS Rubber Pad