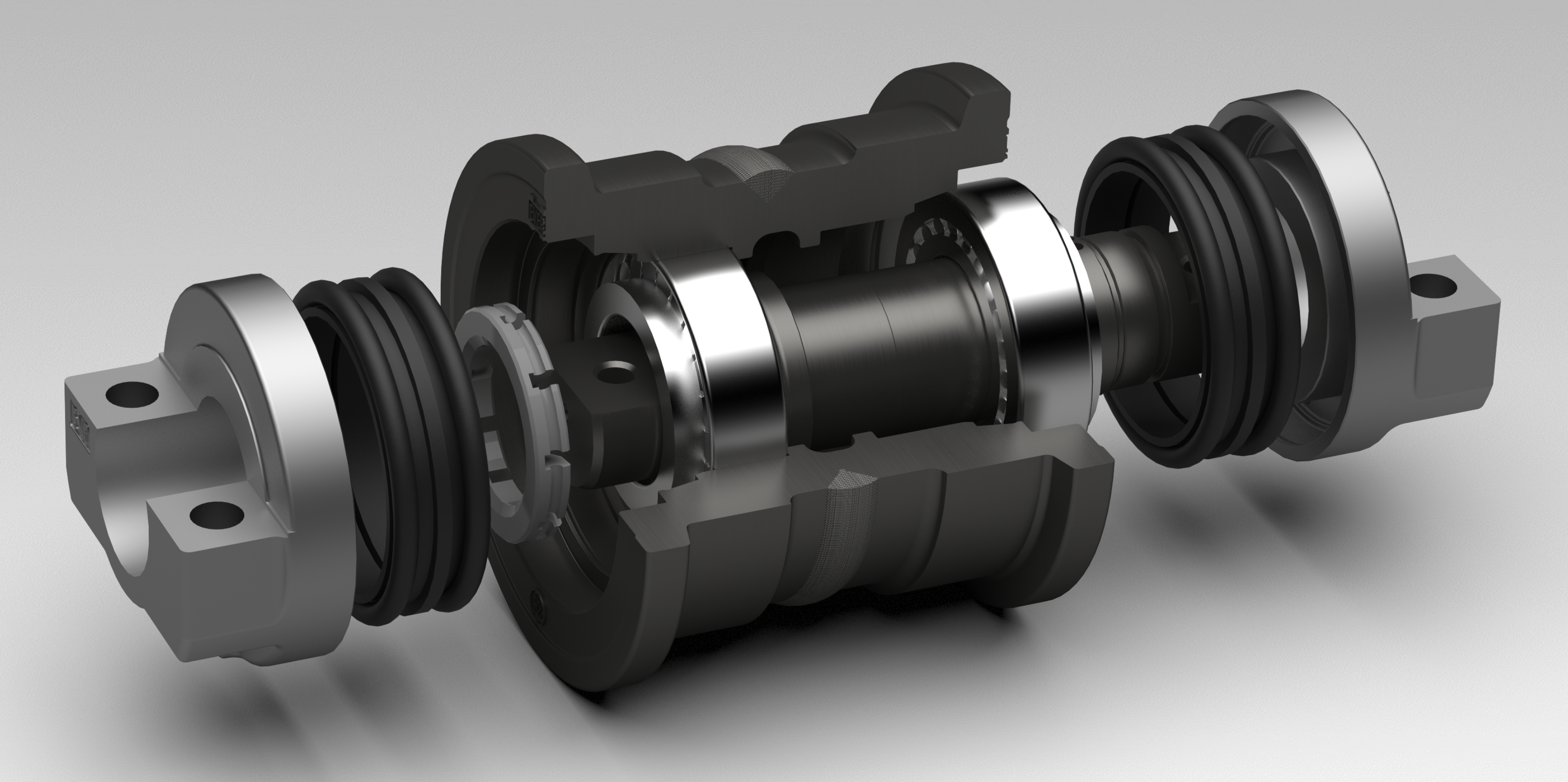

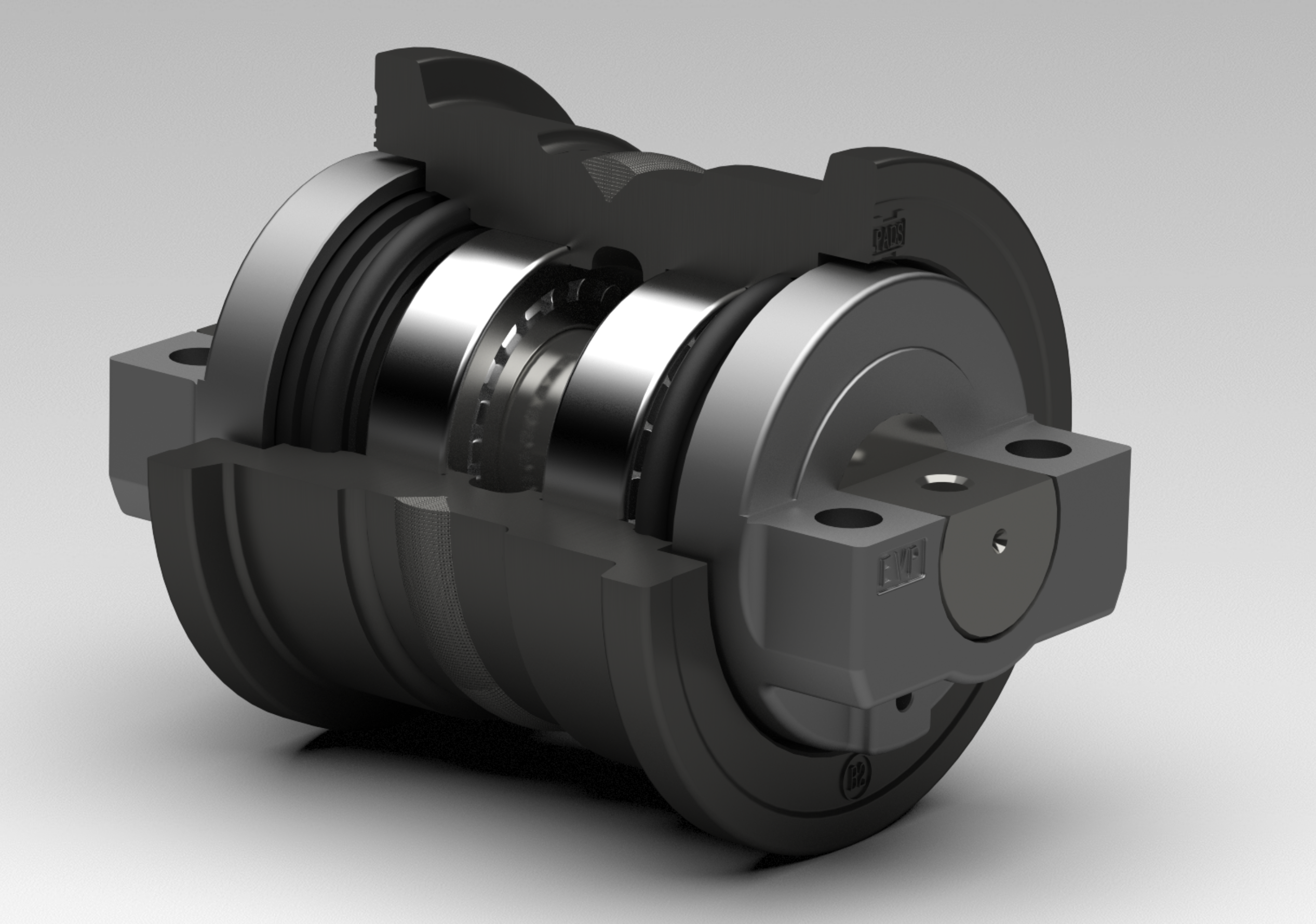

Skill: We produce roller bearing type of track roller

I. Normally it is made of 40Mn2 material, forging, machine process, followed byheat treatment.

The hardness of the wheel tread after intermediate frequency quenching must increase to about 52 degrees HRC.

II. Axle of the track roller is 35 chromium molybdenum, after quenching treatment and finishing.

III. Using imported roller oil for internal lubrication, which is reliable and good at cooling.

IV. Imported floating oil seals and sealing rings, increasing life span.

V. Imported bearing, with good rolling coefficient and generate no heat.