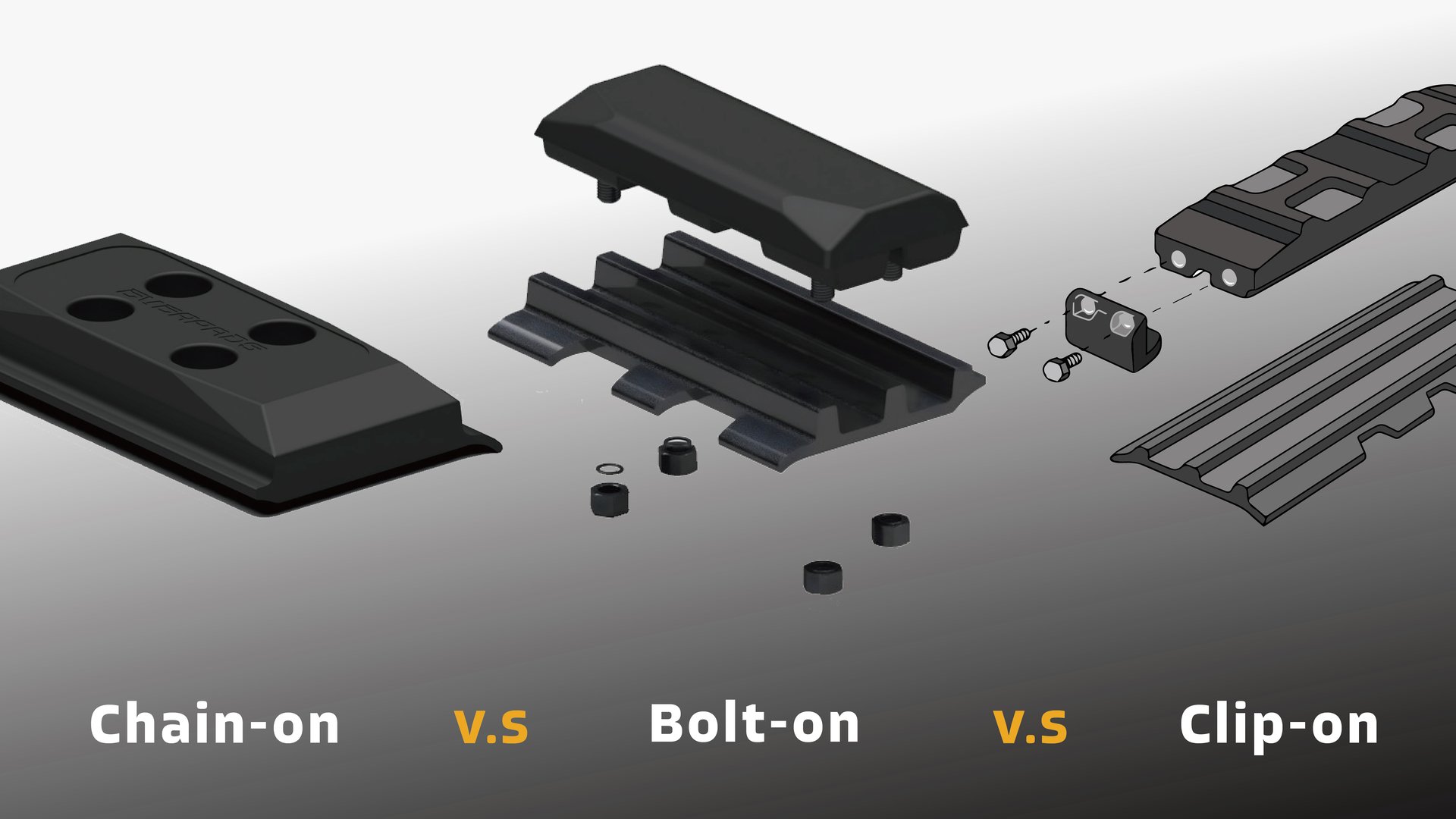

Track pads are essential for heavy equipment, providing traction and protection to the machine as it moves across the road surface and different terrains. In this guide, we will discuss the three main types of track pads: bolt-on, chain-on, and clip-on. We will explore their features, benefits, and applications to help you make an informed decision on the best fit for your equipment needs.

Table of Contents:

1. Bolt-on Track Pads

2. Chain-on Track Pads

3. Clip-on Track Pads

4. Track Pad Material Options

5. How to Choose the Right Track Pad

Bolt-on Track Pads

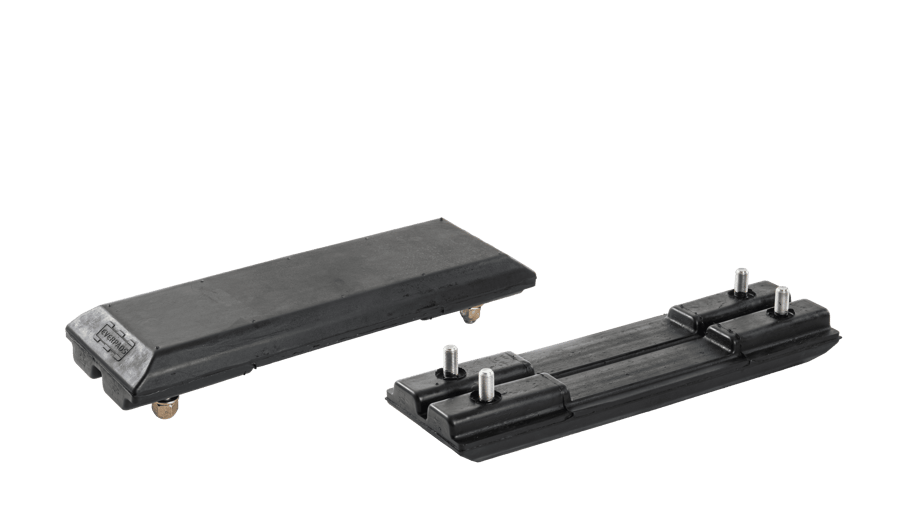

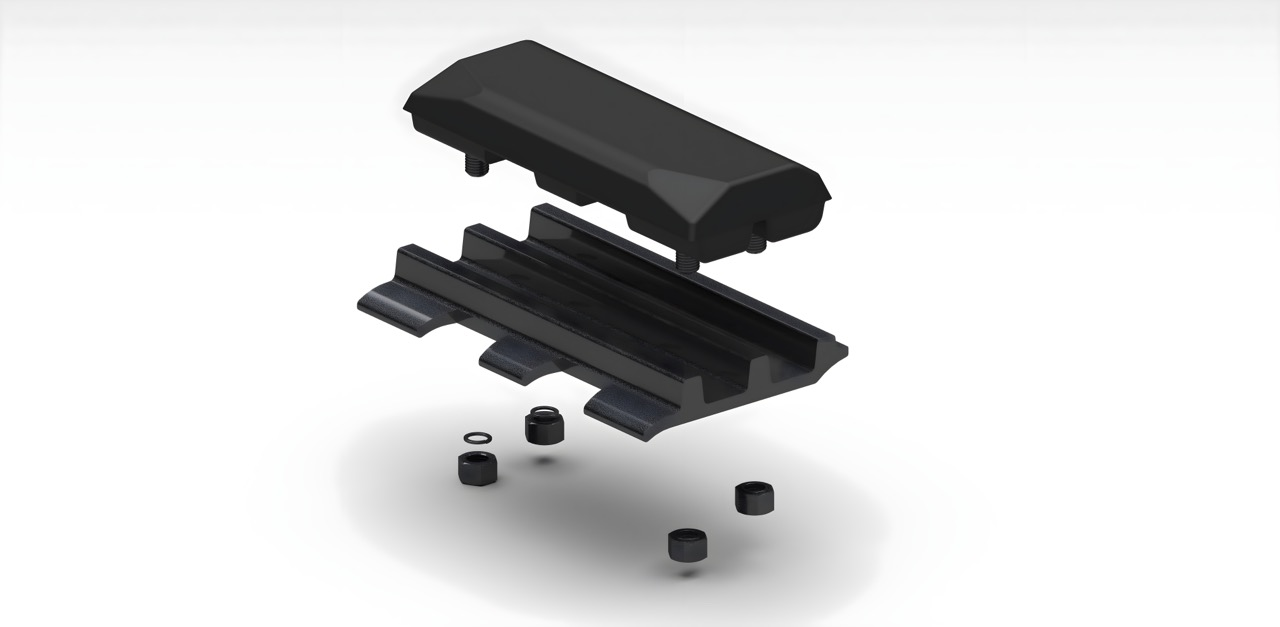

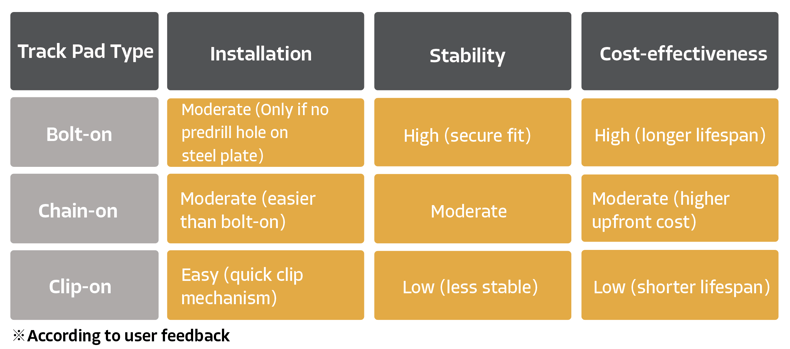

Features and Benefits Bolt-on track pads are the most common type, known for their durability and ease of installation. They attach directly to the track shoe with bolts, providing a secure fit that can handle demanding tasks. Bolt-on pads are cost-effective and generally offer a longer lifespan than other types.

Application

Bolt-on track pads are suitable for a wide range of heavy equipment, including asphalt milling machine, excavators, bulldozers, and pavers. They are ideal for projects that require extra stability and a solid connection between the pad and the machine.

Advantages:

-

Durability: Bolt-on pads are known for their long-lasting construction and resilience.

-

Secure fit: They attach directly to the track shoe with bolts, ensuring a stable connection.

-

Cost-effective: These pads generally offer a longer lifespan than other types, making them a more economical choice in the long run.

-

Easier maintenance: These pads can be replaced individually, reducing downtime during maintenance.

Disadvantages:

-

Installation: If there are no predrilled holes in the excavator's steel plate, you will need to drill holes for bolt-on track pad installation. This can be more time-consuming compared to the clip-on installation process.

Chain-on Track Pads

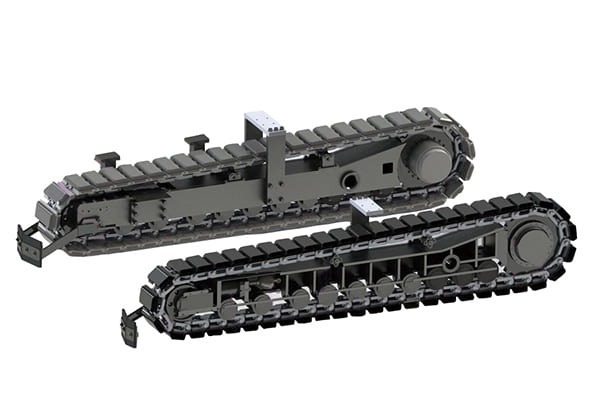

Chain-on track pads are designed with a chain system that wraps around the track shoe, ensuring a tight grip. These pads offer a higher level of flexibility, making them suitable for uneven terrain. They are also easier to replace individually, reducing maintenance downtime.

Application

Chain-on track pads work well with larger machines that need greater adaptability on rough terrain, such as forestry and mining equipment. They are best for jobs requiring constant maneuverability and a strong grip.

Advantages:

-

Flexibility: Chain-on pads offer a higher level of adaptability on uneven terrain due to their chain system.

Disadvantages:

-

Cost: Chain-on pads may have a higher upfront cost compared to bolt-on pads.

-

Lifespan: They might not last as long as bolt-on pads, depending on the work environment and usage.

-

Maintenance: Dust and debris can often get stuck in the bolt holes of chain-on pads, which can lead to more time to cleaning or maintenance needs.

Clip-on Track Pads

Clip-on track pads are the easiest to install and remove, being installed using a clipping mechanism that attaches to the sides of the track shoe. They offer a quick solution for switching between different pad types, making them ideal for projects with varied requirements. However, their lifespan may be shorter compared to bolt-on or chain-on pads.

Application

Clip-on track pads are suitable for machines that need to switch between different surfaces frequently, such as construction equipment operating on both paved and unpaved areas. They provide versatility and can be used in combination with other pad types.

Advantages:

-

Easy installation: Clip-on pads are the simplest to install and remove, using a clipping mechanism that attaches to the sides of the track shoe.

-

Versatility: They provide a quick solution for switching between different pad types, making them ideal for projects with varied requirements.

Disadvantages:

-

Shorter lifespan: Clip-on pads may have a shorter lifespan compared to bolt-on or chain-on pads due to their clipping mechanism.

-

Less secure: The attachment method may not be as stable as bolt-on or chain-on pads, potentially affecting performance in demanding tasks.

Track Pad Material Options

When choosing track pads for your heavy equipment, it's important to consider the materials used in their construction. The most common materials are rubber, polyurethane, and steel. Each material has its unique properties, which can impact the performance, durability, and suitability of track pads for different applications.

Rubber Track Pads

Rubber is a popular choice for track pads due to its flexibility, shock absorption, and noise reduction properties. Rubber track pads provide excellent traction on various surfaces and minimize ground disturbance, making them suitable for use in urban and residential areas.

Advantages:

-

Versatility: Rubber track pads perform well on various surfaces, including asphalt, concrete, and dirt.

-

Noise reduction: The material dampens vibrations and noise, making it ideal for projects in noise-sensitive areas.

-

Ground protection: Rubber track pads minimize damage to delicate surfaces, such as lawns and sidewalks.

Disadvantages:

-

Durability: Rubber track pads may wear out faster than other materials, particularly in harsh conditions or with heavy usage.

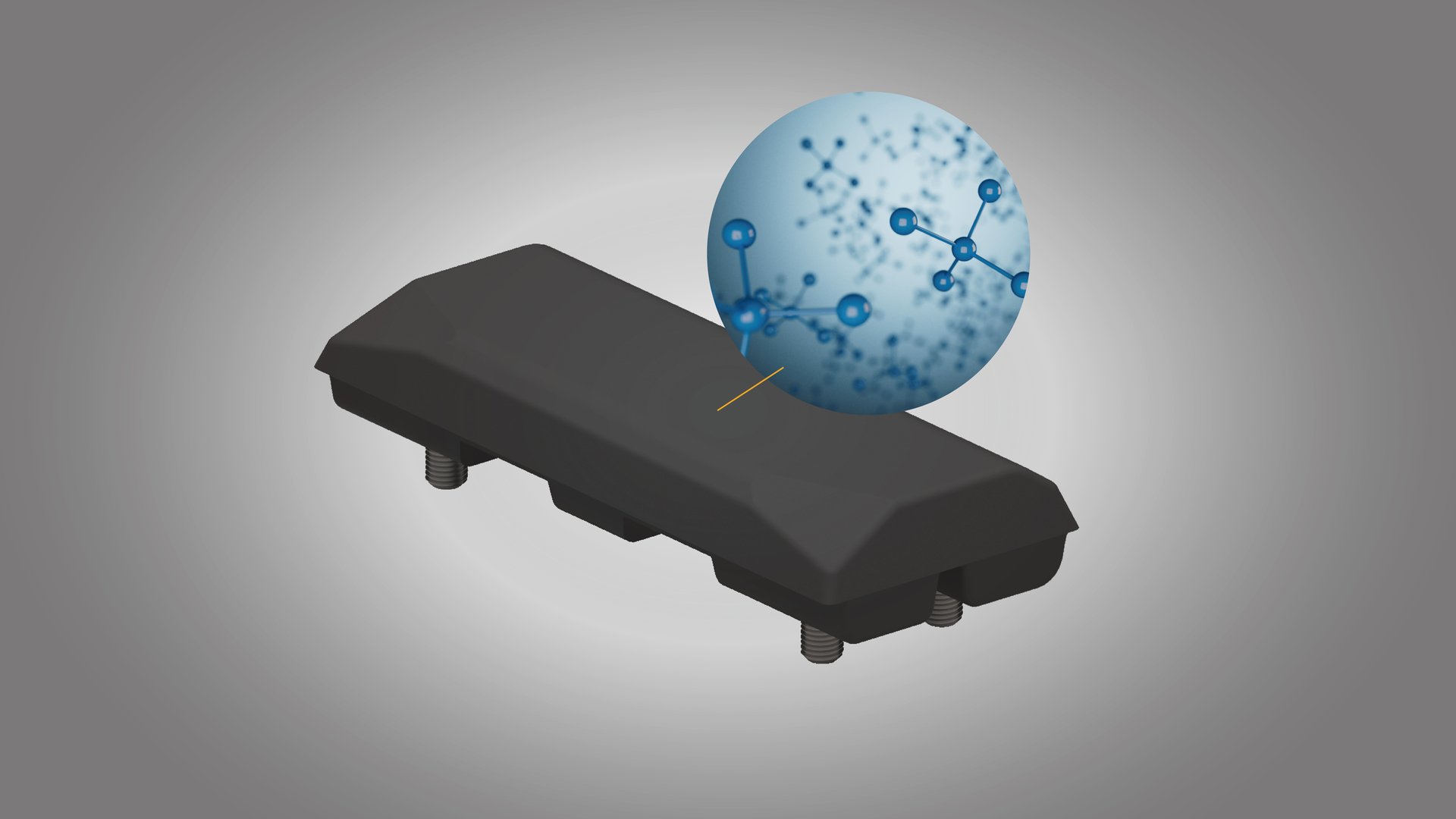

Polyurethane Track Pads

Polyurethane track pads offer a balance between durability and flexibility. These pads are more resistant to abrasion and tearing than rubber, providing a longer lifespan without sacrificing performance on various surfaces.

Advantages:

-

Durability: Polyurethane track pads are more wear-resistant compared to rubber pads, resulting in a longer service life.

-

Performance: They offer a good balance of traction and flexibility, making them suitable for a wide range of applications.

-

Disadvantages:Cost: Polyurethane track pads may have a higher upfront cost than rubber pads, although their longer lifespan can offset this expense.

How to Choose the Right Track Pad

Assess Your Equipment

Take into account the weight and type of heavy equipment you're using and its specific requirements. Different machines may have different track pad compatibility, so it's essential to check the manufacturer's recommendations.

Consider Your Work Environment

Analyze the terrain and working conditions your equipment will encounter. For rough or uneven surfaces, chain-on track pads offer greater adaptability. In contrast, bolt-on pads provide stability and durability on stable ground.

Budget Constraints

Evaluate your budget and prioritize the features that are most important to you. Bolt-on pads are generally more cost-effective, while clip-on pads offer versatility for machines that frequently switch between surfaces. Consider maintenance costs, as some track pad types may have a longer lifespan or be easier to replace.

Choosing the right track pad for your heavy equipment is crucial for efficient operation and longevity. By understanding the differences between bolt-on, chain-on, and clip-on track pads, you can make an informed decision that best suits your equipment and project needs. Always consider factors such as the type of equipment, work environment, and budget constraints to ensure optimal performance and productivity.

Need expert advice on selecting the perfect track pad for your equipment? EVERPADS can provide expert guidance tailored to your specific requirements.

Contact our team today to discuss your track pad needs and discover the ideal solution for your heavy equipment. Experience the EVERPADS difference – quality, reliability, and unmatched customer support.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)