How to Choose the Right Asphalt Milling Machine for Your Project

28. Apr. 2023

Selecting the right asphalt milling machine for your project is essential for achieving the desired outcome. With a wide range of brands and models available, it can be challenging to determine which machine best suits your needs.

In this article, we'll discuss the key factors to consider when selecting an asphalt milling machine and provide recommendations on some popular brands.

Evaluate Your Milling Project Requirements

Before choosing an asphalt milling machine, it's essential to evaluate your job requirements. This includes factors such as:

Size and Scope of the Project

The size and scope of your project play a crucial role in determining the right type of milling machine. Smaller projects may require compact asphalt milling machines, such as the Wirtgen W 50 Ri or the CAT PM102.

Not all asphalt milling machines can handle different types of milling, There is always the right asphalt milling machine for a specific project. For larger projects with harder materials and more extensive surface milling needs, consider more powerful and larger milling machines, such as the Wirtgen W 250 or the Bomag BM 2200/75.

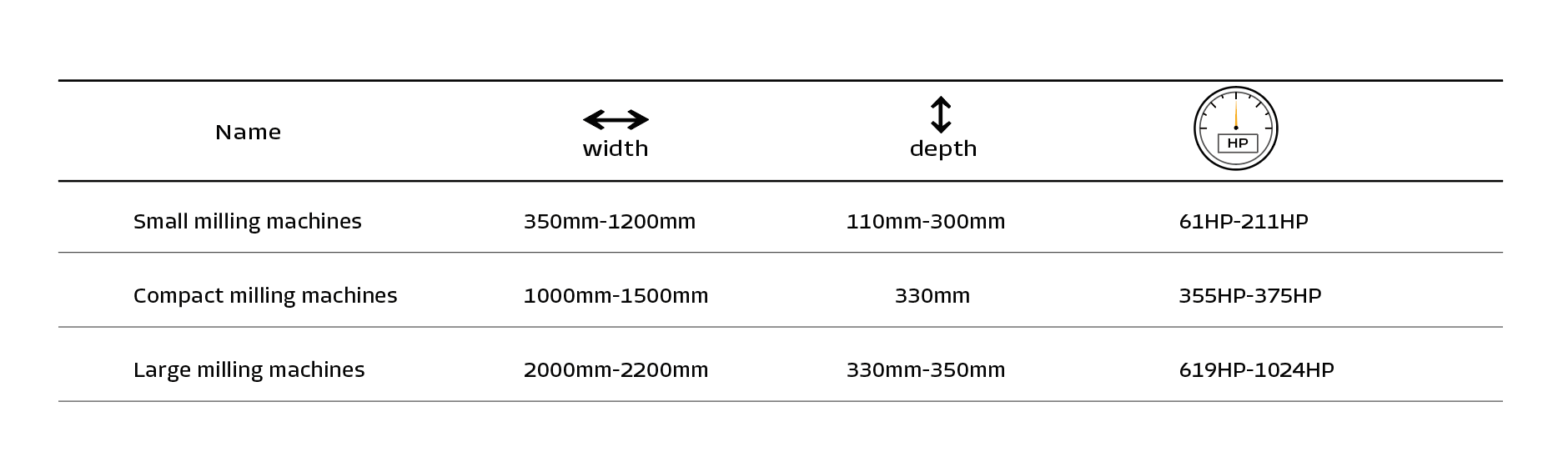

Milling Depth and Width

The milling process, depth, and width requirements are significant factors in the process of choosing the right machine because they are different types of milling. Ensure that the asphalt milling machine you select can achieve the desired milling process, operation, cutting depth, and width based on your project's specifications.

For example, some milling machines offer fine milling capabilities and better use of reclaimed asphalt pavement such as the Wirtgen W 210 Fi, which can mill up to 330 mm deep and 2,200 mm wide.

Maneuverability and Accessibility

Consider the project site's terrain and accessibility before selecting the right milling machine. Smaller, more compact asphalt milling machines are easier to maneuver in tight spaces and on challenging terrain than larger milling machines.

If your asphalt milling operation requires maneuvering in confined spaces, choose milling machines with a smaller milling width, such as the Wirtgen W 100 CFi.

Material Removal and Recycling

It is worth noting that some projects may require the recycling of milled materials from existing asphalt(which are also environmentally friendly). In this case, opt for milling machines with an integrated material removal and recycling system, such as the Wirtgen W 380 CRi. This feature allows you to reuse milled pavement material for new paving, reducing waste and overall project costs.

Budget and Operating Costs of Milling Machines

Finally, consider your budget and the machine's operating costs. While a new milling machine that is advanced and powerful may come with a higher price tag, it can offer higher speeds, a smoother surface, and increased efficiency, ultimately reducing project duration and costs.

Keep in mind that a higher quality machine with higher fuel efficiency and lower maintenance requirements can save you money in the long run.

By considering these factors, you can choose the right asphalt milling machine for your project, ensuring efficiency, cost-effectiveness, and a successful outcome.

Consider the Right Milling Machine Size and Power

When selecting an asphalt milling machine, it's essential to consider the machine's size and power. These factors will significantly impact the efficiency and effectiveness of your milling operations. Here are some aspects to consider:

a. Horsepower

The power of a milling machine is measured in horsepower (hp), and it directly affects the milling cutter ability to remove asphalt efficiently. Higher horsepower milling machines can handle more challenging projects and go deeper past the asphalt pavement into the asphalt layers.

Consider the required milling depth and the asphalt's hardness to choose a machine with appropriate horsepower.

For smaller jobs, machines with around 100-200 hp, such as the Wirtgen W 50 Ri, may suffice. However, for larger projects with greater milling demands, the right milling machine can be one with 500-800 hp, like the Wirtgen W 250 or the Bomag BM 2200/75.

b. Machine Weight and Dimensions

The weight and dimensions of a milling machine can impact its maneuverability and ease of transport. Heavier milling machines may require specialized transportation equipment and additional permits, increasing overall project costs.

Additionally, larger machines may struggle in confined spaces or on uneven terrain.

Choose a machine with a suitable size and weight for your project requirements, ensuring that it can be transported easily and maneuvered on the job site. Compact machines, like the CAT PM102, are ideal for smaller projects and tight spaces, while the right milling machine for extensive milling operations is the larger machine.

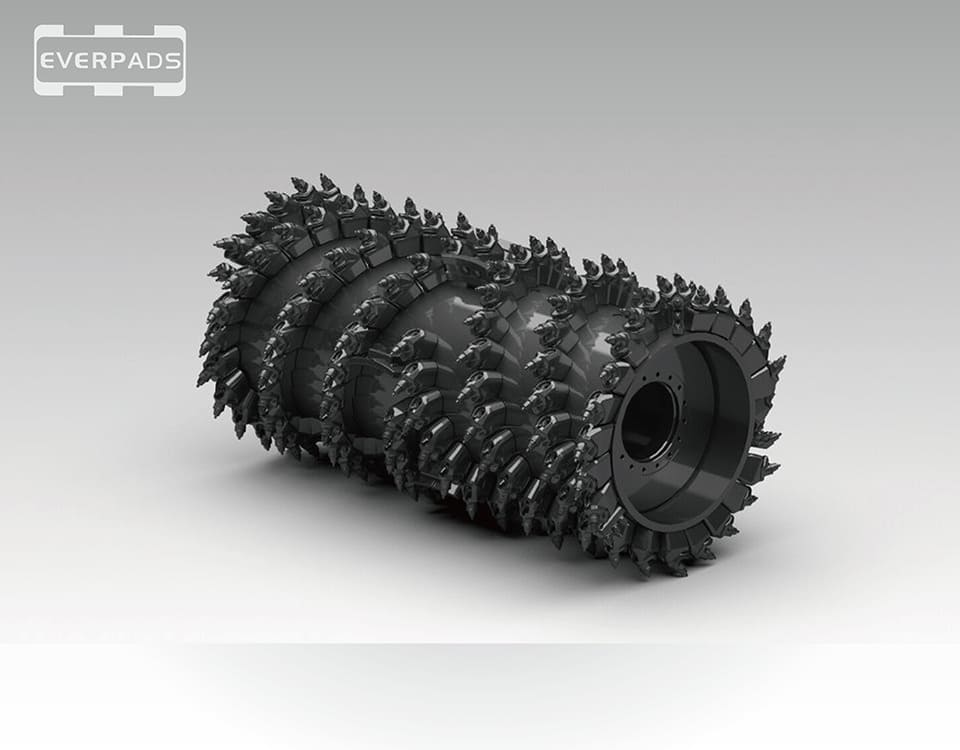

c. Milling Drum

The milling drum is a critical component of an asphalt milling machine, as it determines the machine's milling surface, width, and depth capabilities. Milling machines with larger drums can perform micro milling on the surface, both wide in surface and deeper in a single pass, increasing overall productivity.

However, these machines may be less maneuverable in tight spaces or uneven surfaces.

When selecting a milling machine, ensure its milling drum size aligns with your project's requirements. Smaller drums, like those found on the Wirtgen W 100 CFi, are suitable for projects with space constraints, while larger drums are ideal for projects with significant milling needs.

Everpads offers a range of milling drums suitable for different machine sizes and project requirements.

d. Traction System

The traction system of a milling machine is crucial for maintaining stability and maneuverability during operation. Machines with advanced traction systems, such as those equipped with rubber track pads, can improve performance on challenging terrain and reduce damage to the surrounding pavement.

Choose a milling machine with a suitable traction system for your project site, considering factors such as ground conditions, inclines, and accessibility. Machines like the Wirtgen W 210 Fi, which features an advanced traction system, can provide increased stability and performance on various surfaces.

Examine Features and Technology

Asphalt milling machines come with various features and technologies, that impact their performance, efficiency, and overall productivity. When selecting a machine, consider features such as:

-

Advanced control systems

-

Enhanced cutting tool wear analysis

Explore how to evaluate your teeth by their wear conditions:

5 Typical Road Milling Teeth Wear & Tear

-

Ergonomic design for operator comfort

-

Efficient dust and debris management systems

Some machines, like those from Everpads, incorporate cutting-edge Formula E technology for extended rubber trackpad lifespan and improved performance.

Assess Brand Reputation and Support

When selecting an asphalt milling machine, it's crucial to consider the reputation and support offered by the manufacturer.

A reputable brand typically delivers high-quality machines designed for long-term performance, durability, and efficiency.

Here are some factors to consider when evaluating a brand and its support:

Track Record

Research the manufacturer's track record in the industry, focusing on customer satisfaction, product reliability, and the overall performance of their equipment. Check for testimonials, case studies, and any awards the company may have received.

Customer Service

Assess the company's commitment to customer service, as this will play a crucial role in addressing any issues that may arise during the machine's operation. Look for 24/7 support availability, knowledgeable staff, and prompt response times.

Warranty and Spare Parts Availability

A comprehensive warranty provides peace of mind and protection for your investment. Verify the warranty terms and coverage offered by the manufacturer.

Additionally, ensure that spare parts are readily available and reasonably priced to avoid downtime and costly repairs.

EVERPADS provides premium spare parts without premium costs for maintenance and repair, ensuring you can keep your machine in top condition without breaking the bank.

Training and Technical Support

A good milling equipment manufacturer should offer training and technical support to help you operate and maintain the milling machine efficiently. This support should include user manuals, online resources, on-site training, and remote assistance when needed.

Innovation and Technology

Investigate the manufacturer's commitment to innovation and technology, as this is an important factor that will impact the machine's performance, safety features, and ease of use.

Look for features such as advanced control systems, automation, and cutting-edge milling drum designs.

By carefully assessing the brand reputation and support offered by a reputable dealer and the manufacturer, you can ensure that your investment in an asphalt milling machine will be well-protected and provide a high return on investment over time.

Some popular brands include:

-

Wirtgen

-

CAT

-

Bomag

Additionally, consider the level of after-sales support provided by the manufacturer, including warranty coverage, spare parts availability, and technical assistance.

Explore Everpads customized service on the milling drum production:

The Production and Technology of EVERPADS Milling Drum

Learn Everpads technologies on milling drum production:

Revolutionizing Road Construction: Everpads' Gen-E Milling Drum

Compare Pricing and Value

When purchasing an asphalt milling machine, it's essential to strike a balance between cost and value. The initial purchase price should be considered alongside factors such as performance, durability, and maintenance costs.

Here are some points to keep in mind when comparing pricing and value:

Initial Cost

Compare the prices of different models and manufacturers, taking note of the features and specifications that each machine offers. Remember that the cheapest option may not always provide the best value in the long run if it sacrifices performance or requires frequent repairs.

Operational Costs

Consider the machine's fuel efficiency, as this will impact the overall cost of operation. Additionally, evaluate the cost of consumables, such as cutting tools, and the availability of affordable, high-quality replacement parts.

Explore How to evaluate a milling tooth's design

Maintenance and Repair

Assess the ease of maintenance and the availability of cost-effective solutions for repairs. Simple maintenance procedures and readily accessible components can help reduce downtime and labor costs, while a reliable source of spare parts can minimize repair expenses.

Resale Value

The resale value of the milling equipment or machine should also be taken into account. A new machine, with a strong brand reputation and a history of reliable performance, is more likely to hold its value over time, providing a better return on investment.

Financing Options

Explore financing options offered by manufacturers or third-party lenders, such as leases or loans, to find the most suitable payment plan for your budget. Keep in mind that interest rates and terms can vary, so it's important to carefully review the terms before committing.

By weighing these factors, you can make a more informed decision when selecting the right asphalt milling machine for your project.

Conclusion

Selecting the right asphalt milling machine is crucial to the success of your project. By carefully considering your project requirements, machine size, and power, features and technology, brand reputation, and overall value, you can find the perfect machine to meet your needs. To explore a wide range of milling machines and related products, visit the Everpads catalog and discover the perfect solution for your project.

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)