Pile driving hammers have been considered one of the greatest inventions among building equipment. It has been used in building a deep foundation project for as long as they have been around. It is a heavy piece of equipment but very effective especially for setting foundations whose depth is more than three times its breadth.

What is a pile driver and what sets it apart from other pile driving equipment?

A Pile hammer is a heavy construction equipment that is designed and engineered to drive piles into the ground to set a deep foundation and other related construction projects. Setting piles into the soil requires a rapid number of downward blows and impacting jaws to grip and position the piles into the ground through pile driving equipment.

Pile driving hammers are of different types and engineered for different purposes. For instance, what is used to extract piles from the soil is different from what is used to drive piles to create support for structures like retention ponds and steel piling. Although there are pile driving hammers that are for extraction purposes and used to drive piles at the same time.

Pile Driving Hammers Comes in Different Types

-

They are mainly: Hydraulic impact pile driving hammers, Air/steam impact pile equipment, Diesel impact pile driving equipment, Vibratory pile driving equipment, including the Drop forging hammers.

-

Each of them features a distinguishing purpose but the vibratory type is the most productive and effective driving equipment among them. It remains the best method of driving steel sheets and other piles in and out of the soil.

-

It loosens the soil faster and is great at driving steel pipe, due to the way it drives components into the soil including resetting driven piles.

-

Knowing the differences and how it works will help you know the right pile driving equipment for any pile driving purpose. It will further make you look less of a novice.

Read further to find out different types of pile driving equipment and how it works. Let's get started, shall we?

Types of Pile Hammers

Types of pile driving equipment more accurately reflect the meaning of the phrase “types of pile drivers.” This definition includes Hydraulic impact pile drivers, Air/steam impact drivers(or a steam hammer), diesel hammer, and Vibratory pile drivers.

1. Hydraulic Impact Pile Driver

Hydraulic vibro hammer sheet pile driving is a powerful and efficient way to drive piles into the ground for construction projects. It employs an excavator-mounted vibratory hammer that is coupled to a heavy-duty hydraulic hammer that drives the pile in with the power of the excavator's engine. This approach can be utilized on any type of excavation project, from small home foundations to huge industrial ones, and it is capable of quickly and efficiently breaking up soil and rock. This tool's vibrations are powerful enough to offer quick results while keeping prices low, making it a vital piece of equipment for any construction operation.

Hydraulic hammers are similar to diesel impact hammers. The only difference is that the hydraulic impact hammer is more modern compared to diesel and air hammers.

It is powerful foundation equipment that is capable of driving precast concrete piles, including steel piles and beams. Its main energy source is the hydraulic power packs.

Even though it's similar to diesel hammers, a hydraulic hammer is more eco-friendly. It is capable of hitting 80 blows per minute while operating without exhaust fumes expelling into the air. It features a high productivity rate and it's capable of driving timber piles, H-piles, a steel sheet pile, and other concrete piles within a short time with lesser noise.

As a piece of construction equipment, its essential roles are enormous. It can be used for different concrete piles including building and demolition in the construction industry.

For other structures, hydraulic hammers are capable of breaking dirt to dig a hole, breaking rocks, and setting deep foundations and driven piles.

For demolition purposes, it can break through tough materials, walls and uproot deep foundations.

The hydraulic hammer mainly consists of two hammer types, one features an inner valve while the other features an outer valve. They perform the same function and feature the same inner parts, which includes:

Nitrogen chamber: this helps to provide power that makes hydraulic hammers function.

Front cap: helps to keep the hammer extension safe during operation

Main valve: the moving part that assists the hammer during impact.

Side rods: This part is engineered to support hoisted hammer application.

2. Air or steam impact Pile Hammers

Air or steam hammers can also be seen as drop hammer. It is an industrial construction hammer run by steam to drive piles.

The steam is a compressed air pressure that is released automatically to raise the ram in a drop hammer. The steam hammers are suitable for different pile-soil combinations (including sheet piles) but function efficiently when shaping forgings, driving H-piles, and timbers into the sand.

The power source of a steam hammer is mainly steam boilers which help the ram to strike the drive cap. It comes in different designs, some are usually attached to a piston, while some are affixed to a cylinder.

Steam hammers attached to a piston usually slide within a static cylinder while the one attached to a cylinder skid along with a set piston. The air compressors aid its functionality, which helps to power the ram upward or downward.

Air/steam impact pile driver is classified into two, which are:

Single Acting Hammer

The compressed airlifts the heavy ram during operation. When lowering, the hammer lowers by its weight. To get the energy of a single-acting hammer, multiply the weight of the ram and the falling height at its highest point.

On average, it can hit 50-60 blows per minute. It works in all soil conditions.

Double Acting Hammer

The compressed airlifts the ram to help speed up the downward stroke. Upon accelerating the stroke, the frequency of blows is usually increased (90-150 per minute).

The double-acting hammer applies extra steam or compresses air to the piston to facilitate faster speed. It can drive and extract piles at a fast speed without consuming much headroom.

The total energy of a double-acting hammer comprises ram weight, the effective area of ram multiplied by its fall.

3. Diesel Impact Pile Hammers

Diesel hammers have an increased compression pressure that rides the piston. It is also a necessity in the pile foundation industry.

The diesel pile driver falls under the category of drop hammers among construction equipment. It features a diesel engine that has a two-stroke and uses diesel fuel. The pump lever is triggered by the piston upon the drop of a diesel hammer.

Air mixture and compressed diesel fuel ignite the power of a diesel pile hammer while transporting its energy to the pile head.

The diesel engine operation mode is in stages, which are:

Fuel is injected when the ram is put up:

Compression

At this point, air and fuel are compressed together due to the closing of the exhaust. It also drops freely as the ram is expelled.

Effect and Combustion

The air/fuel combination is heated and ignites as a result of the compaction. It also features a flexible fuel pump that regulates the piston, so that when it's operating, the pile attains impact with the hammer.

Expansion

When the hammer weight reaches impact, the pile gets into the soil. This impact also causes the ram to drive upwards. At this point, fresh air will be present, and the cycle will begin again until all the fuel is drained or it's halted by the builders.

Diesel hammers are also great during a soil formation change. Another advantageous feature is the sufficient power supply it has without depending on any external power source.

Within a minute, a closed-end diesel hammer can reach 30 to 50 blows. There is also an open-end type that can reach 70 to 80 per minute.

4. Vibratory Pile Hammers

Vibratory hammers have good a impact block especially when clay deposits are present. Soils with palpable numbers of pebbles will be difficult to set with other hammers, but vibratory hammers can drive piles into a hole with heavy clays.

Unlike other hammers that drive piles into soils, a vibratory driver cuts into the ground. It uses a spinning process when operating through the power of hydraulic motors.

Despite the gravity force and great speed of impact its features, it has less noise compared to others. It is engineered to make horizontal vibrations when operating, the vibration is then counterbalanced with vertical vibrations. After this, the vibration is transported to drive the pile down.

Vibratory hammers can also perform temporary extractions from a pipe pile from crane access trestle and cofferdams. It is capable of going far above 3000 feet below the earth's surface.

This piling hammer operates at a high frequency while delivering up and down vertical impulses. To quicken the impact, the pile weight functions with the pulse to boost gravity force.

The vibratory piling hammer is the most preferred pile driver due to its functionality, speed, and less noise when driving piles including sheet piles.

Types of Vibratory Hammers

Excavator Mounted Vibratory Hammer

An excavator mounted vibratory hammer is a type of construction equipment that uses vibration to drive piles or sheet piling into the ground. It works by connecting an excavator boom arm to a heavy-duty hydraulic hammer and then driving the pile in using the power of the excavator's engine. This technology is applicable to all types of excavation, from small residential foundations to huge industrial operations. This tool's vibrations are strong enough to break up soil and rock, allowing you to make speedy progress on any project you're working on. If you require rapid, dependable results while keeping your prices down, an excavator mounted vibratory hammer is a must-have piece of equipment.

Read further to find out how a pile driving machine works.

How Does a Pile Hammer Work?

The vibratory hammers fall under the modern pile drivers and they are mostly used today(especially in pile foundations) due to their low impact noise(despite the effective functionality).

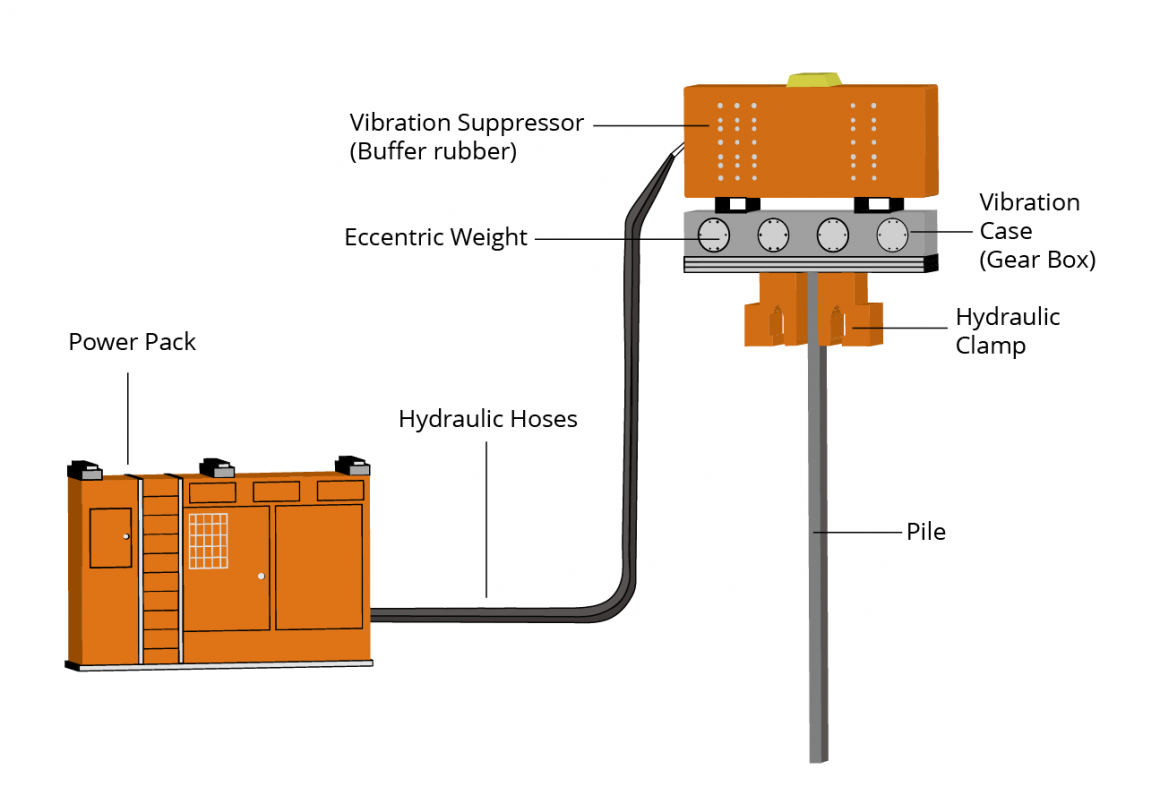

A modern vibratory hammer works by transporting vertical vibrations to the pile through a hydraulic clasp.

The transported vibration decreases the friction between the soil and the pile. Whether you are setting a pile or extracting one from a foundation, high force is needed through the provision of a good rubber buffer.

It operates by opposing the friction of the ground and changing the earth's surface formation through vibration.

Its main components are the gripping jaws, a gearbox(also known as the vibration case, centers, elastomers, suppressor housing, eccentric shaft, and a clamp.

The vibration case helps it to produce a constant cycle of vibration to lessen dominant noise.

The eccentric shafts are clambered in huge roller bearings to aid synchronization.

The suppressor housing helps to separate pulses from the vibration case to the pile, while the hydraulic clamp uses its gripping jaws to move and check the valve to avoid hose damage.

How to Maintain Your Pile Hammer

The vibratory pile driver is the heart of a deep foundation project, it needs to function smoothly to keep the construction project ongoing. The importance of proper maintenance cannot be overemphasized, here are 5 pile driver maintenance tips that will help the vibratory hammer to keep functioning.

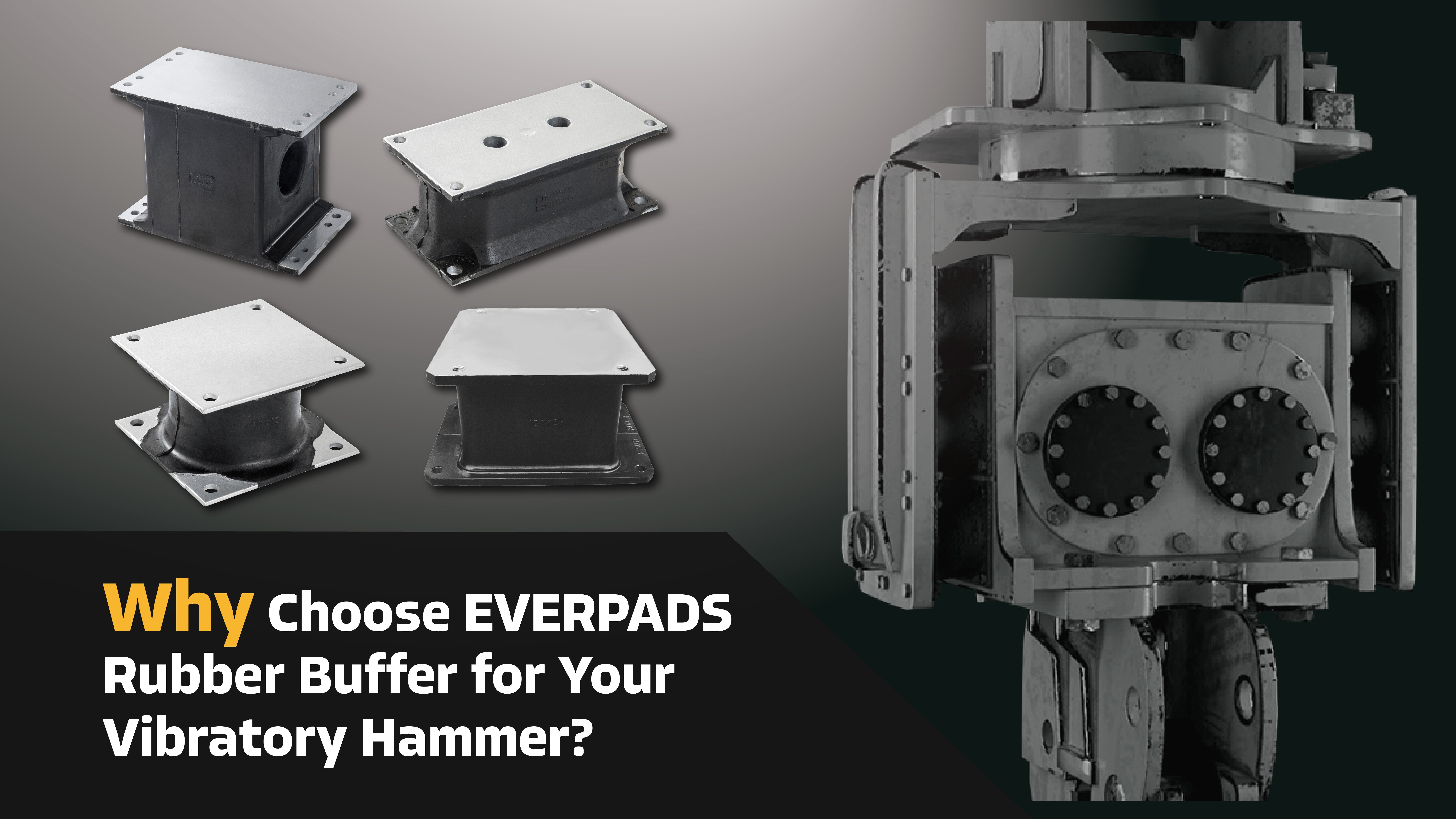

1. Check Your Rubber Buffer

Rubber buffer is the main component that prevents the vibratory hammer from being damaged. As a pile driver operates, the vibrating frequency and the driving force are usually high, a high-quality rubber helps dampen the pulling force and vibration frequency.

Also, if one of the rubber buffers goes bad, trying to manage it without a replacement will result in an uneven mechanism.

During maintenance, opt for rubber buffers that will increase hardness and elasticity. EVERPADS has decades of experience in manufacturing vibratory hammer parts. No matter the vibrating frequency or workload, EVERPADS rubber buffer can handle it effectively.

2. Clean Up After Every Use

Hammers are prone to dust, endeavor to clean it after every project, depending on the surface area that needs cleaning, oil or water may be needed for thorough maintenance.

3. Examine the Screws/Clamp Jaws

Check for loose screws and tighten them to aid efficiency. Check for rust around the teeth clamp jaws, if they seem worn out or corroded, consider replacing them to avoid damage.

4. Check the Power Pack

Warm up the power pack before the operation, check if there's any oil leakage or a malfunction. If there's any, it may need to be changed or have an expert look at it.

Always check the hydraulic fluid level in the power pack, ensure it's at a standard point.

5. Check hoses

Vibratory hammer hoses are prone to wear and tear. To avoid leakage and improper oil flow, carry out a routine inspection to ensure they are properly connected to the vibrator hammer’s power pack and without leakage.

6. When not In-use, turn it Over to the Other Side

Leaving an unused vibratory hammer on one side over a long period prevents proper oil circulation. To easily keep it lubricated and ready for use, simply flip it at intervals.

7. Check the Expansion Tank:

Always check your expansion tank level to make sure it is enough. You can top it if it is below standard.

Common Mistake You Should Avoid

When working with pile hammers, things can quickly go wrong, here are 7 important mistakes you should avoid:

-

Perform a soil analysis to determine the expected blows needed to drive piles.

-

Always inspect the nature of the SERPENTINE BELT: make sure it's not too tight or too loose. A loose serpentine belt cannot provide the max power needed for your equipment to function. Also, if it is too tight, the risk of breaking during operation is high.

-

Secure permits and check for authorization to ascertain a safe work area.

-

To avoid damaging the pile toe, always inspect the soil conditions through borings.

-

To prevent pile hammers from driving out of location, check the alignment control or lookout for any soil impediments.

-

Pay Attention to Small Details. Trust your common sense in case you see something improper. A structure may be close to collapse in case of extraction, you need to be alert to stay out of the way.

-

To avoid driving piles deeper than expected, you can perform restrike tests. This will help you assess the changes in soil strength.

Conclusion

Getting to know what a pile driver is, its types, and how it works entails a lot, but not more than you could expect from other construction equipment. With a modern type vibratory driver, you can easily drive steel sheets and other piles in and out of the soil and avoid inefficient pile settings. Start by checking out the vibratory pile driver, if you need effective results then carry out proper maintenance regularly.

The aforementioned tips should keep your pile driver healthy and save you a lot of money in repairs/ replacement/ maintenance. Complex parts(especially the rubber buffer) require high-quality materials as you'll get a return favor of long-term value. Talking about value, EVERPADS can get you the best vibratory driver parts in a cost-effective manner, no matter your needs(whether basic or custom). Our rubber buffer is durable, it can withstand the high driving force and vibrating frequency of your pile driver

Trying to decide what vibratory hammers need to keep it in good condition? Contact EVERPADS to discover an effective solution to the rubber buffer of your vibratory hammer including getting it ready for work.

Explore Why Choose EVERPADS Rubber Buffer for Your Vibratory Hammer

.png?width=698&height=417&name=%E5%AE%98%E7%B6%B2logo%20(1).png)